The CSA Z96-22 standard is the definitive Canadian rulebook for high-visibility safety apparel (HVSA). It’s what ensures workers are seen and safe in hazardous environments. The standard lays out the non-negotiable requirements for the design, materials, and use of gear like vests, jackets, and coveralls that protect people working near moving vehicles or in low-light conditions.

Decoding The CSA Z96-22 Standard

Don’t think of the CSA Z96-22 standard as just a dense, technical document. It’s better to see it for what it truly is: a life-saving communication system. Its entire purpose is to make a worker impossible to miss, grabbing the attention of vehicle and equipment operators in any lighting condition, day or night. This standard is the bedrock of safety for anyone whose job puts them in harm's way.

Whether it’s a chaotic road construction site or a quiet utility job at dawn, the risk of not being seen is terrifyingly high. High-visibility apparel is that critical first line of defence. The standard makes sure this defence is reliable by setting clear, minimum requirements for the materials, colours, and reflective components used in every piece of safety gear.

Why This Standard Matters

The core principle behind CSA Z96-22 is simple: visibility equals safety. The standard sorts garments into different classes of protection, much like traffic lights use different colours to communicate caution. A higher-class garment has more visible material, which signals a greater need for awareness from anyone nearby. This systematic approach takes the guesswork out of safety and builds a clear, unified protocol across all Canadian job sites.

At its heart, CSA Z96-22 is all about managing risk by making people conspicuous. It ensures that no matter the environment—be it a rain-swept highway at midnight or a bright, sunny construction zone—workers are given the best possible chance to be seen and stay safe.

Key Updates in the 2022 Edition

This isn't a static set of rules; it evolves to tackle modern safety challenges. The CSA Z96-22 standard for high-visibility safety apparel was officially published on February 28, 2022, marking the fourth edition of this critical Canadian safety spec. This latest version brought in some important modernizations to better align with global best practices, including updated definitions that sync up with American standards.

Understanding these rules is non-negotiable, both for the workers wearing the gear and for the safety managers tasked with protecting them. Proper implementation means picking the right class of garment for the specific job and environment. This guide will walk you through everything you need to know to choose the right high-visibility workwear and ensure your team is fully protected and compliant.

Breaking Down The Three Garment Classes

The CSA Z96-22 standard sorts high-visibility apparel into three distinct classes, and each one is built for a specific level of risk on the job. The best way to think about these classes isn't as good, better, and best, but more like specialized tools for different tasks. You wouldn't use a small finishing hammer for a major demolition job, and you wouldn't wear a Class 1 garment for nighttime highway repair.

Getting a handle on these classes is the very first step in making a smart safety decision. Each class has a minimum requirement for the amount of bright background material and retroreflective striping it needs. This directly links to the level of visibility a worker needs in their specific environment. The higher the class, the more coverage the garment offers, and the sooner a driver can spot that worker.

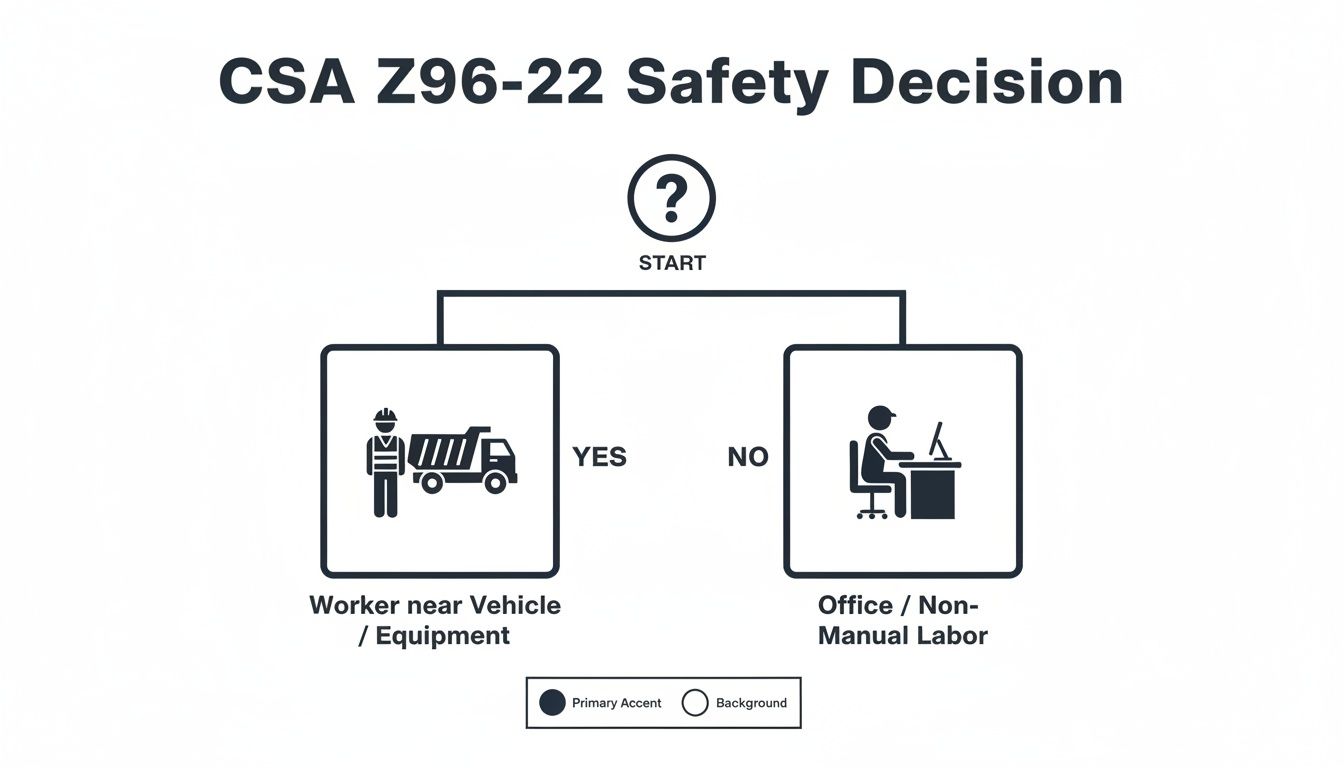

This visual decision tree is a great way to see when high-visibility apparel under CSA Z96-22 becomes a critical part of a worker's safety.

The main takeaway here is simple: a worker's proximity to moving vehicles or equipment is the primary factor that kicks in the need for compliant high-visibility gear.

Class 1 Garments: For Low-Risk Areas

Class 1 gear offers the most basic level of visibility under the CSA Z96-22 standard. These garments are meant for workers in low-risk spots where they are well separated from traffic, and vehicle speeds stay below 50 km/h. The whole point is to make the worker stand out to vehicle operators who are probably already aware they're in the area.

A perfect real-world example is a parking lot attendant or a warehouse worker moving pallets with a forklift. In these situations, vehicle movements are generally slower and more predictable. Class 1 apparel, often just a simple harness or a basic vest, provides that essential visual pop without needing full-body coverage. It just makes sure the worker stands out against their immediate background.

But let's be clear: Class 1 is not suitable for any work near public roadways or in complex, busy work zones. The minimal coverage it provides just isn't enough for environments where a driver's attention is split or where visibility might be poor.

Class 2 Garments: The Standard for Most Roadside Work

Class 2 represents a big jump in visibility and is the most common class required for people working near traffic. It's designed for environments where vehicle speeds are between 50 and 100 km/h and where workers need to be more easily seen due to bad weather or cluttered backgrounds.

Picture a roadside survey crew, a utility worker fixing a line on a moderately busy street, or school crossing guards. These workers are much closer to moving traffic and absolutely need to be visible from greater distances. Class 2 garments provide full coverage of the upper torso—front, back, and sides—to ensure 360-degree visibility. Many types of safety gear, from straightforward vests to heavier jackets, can meet this standard. Taking a look at the range of available hi-vis vest options is a great way to see the variety that meets Class 2 compliance.

Key Takeaway: Class 2 is the essential minimum for most workers who are exposed to traffic as part of their daily job. The extra material coverage significantly cuts down the time it takes for a driver to recognize a person, especially in distracting environments.

Class 3 Garments: For High-Risk Environments

Class 3 provides the highest level of visibility and is mandatory for workers in the most hazardous, high-risk environments. This includes any situation where vehicle speeds push past 100 km/h, where workers are exposed to high-speed traffic at night, or in extremely poor weather.

A nighttime highway repair worker is the classic example. At night, with headlights causing glare and rain slashing sightlines, maximum conspicuity becomes a matter of life and death. Class 3 garments are required to have retroreflective striping on the arms and legs in addition to the torso. This crucial detail outlines the full human form, allowing drivers to recognize a person much faster and from farther away, giving them more time to react. The CSA Z96-22 standard mandates this enhanced coverage because it’s been proven to save lives in these high-consequence scenarios.

To make these distinctions even clearer, here's a quick side-by-side look at what each class is designed for.

CSA Z96-22 Garment Classes At a Glance

| Garment Class | Typical Work Environment & Risk Level | Key Feature Requirement |

|---|---|---|

| Class 1 | Low-Risk: Worker is well separated from traffic. Vehicle speeds are under 50 km/h. (e.g., parking lot attendant) | Provides a basic level of visibility. Focuses on making the worker conspicuous against the immediate work background. |

| Class 2 | Moderate-Risk: Worker is near traffic. Vehicle speeds are 50-100 km/h. (e.g., road construction, utility work) | Offers full 360-degree visibility of the upper torso. This is the minimum standard for most workers exposed to roadway traffic. |

| Class 3 | High-Risk: Worker is exposed to high-speed traffic (over 100 km/h), at night, or in poor weather. (e.g., highway crew) | Provides the highest level of visibility. Requires retroreflective material on the arms and legs to outline the human form. |

This table helps put it all into perspective. Choosing the right class isn't about guesswork; it's about matching the level of protection to the real-world risks your crew faces every day.

Understanding Retroreflective Performance

While the bright, fluorescent background on your hi-vis gear is a lifesaver during the day, it’s the retroreflective material that does the heavy lifting after the sun goes down. This is the tech that makes you light up in the dark, and getting a handle on how it works is key to understanding the real-world impact of the CSA Z96-22 standard.

Ever notice how a cat's eyes seem to glow when caught in your headlights? They aren’t making their own light—they're just reflecting yours directly back at you. Retroreflective material works on the exact same principle. It's covered in thousands of tiny glass beads or microprisms that catch light from a source, like a truck's headlights, and bounce it straight back with almost no scattering.

This direct return of light is what makes a worker suddenly "pop" out of the darkness, giving drivers a few precious extra seconds to see them and react. It’s a simple but incredibly powerful technology that forms the foundation of nighttime and low-light safety.

Levels and Special Designations

Not all reflective tape is created equal. The CSA Z96-22 standard sets out different performance levels to make sure the gear matches the risk.

- Level 1: This offers a lower level of retroreflective performance. Think of it for job sites with more ambient light or where workers are well separated from moving vehicles.

- Level 2: This is the top tier, delivering superior performance by bouncing a much higher amount of light back. It’s a must-have for workers in high-risk zones, especially anyone working on or near high-speed roadways at night.

Beyond the levels, there's another critical detail to look for on the tag: the 'FR' marking. This is non-negotiable, indicating that the retroreflective tape is flame-resistant. For anyone exposed to arc flash or flash fire hazards, standard reflective tape is a serious danger because it can melt and burn. FR-rated tape is essential for dual-compliant garments that protect you from both visibility and thermal hazards.

Why Striping Patterns Matter So Much

The placement of the retroreflective tape is just as important as the material itself. CSA Z96-22 requires specific striping patterns that are designed to send a clear message to drivers in a split second.

The most famous feature is the unmistakable 'X' on the back. This simple design instantly tells an approaching driver that the worker is facing away from them—a critical piece of non-verbal communication that can prevent a tragedy.

On the front, two vertical stripes paired with a horizontal band around the waist help outline the worker's torso, making them visible from the front and sides. This 360-degree coverage is designed to ensure a worker is identifiable as a human figure from any angle. For a closer look at how these patterns work, you can find more detail on different types of reflective striping and where they're used.

A Critical Update for Bib Overalls

The 2022 update brought a huge improvement to visibility, zeroing in on bib overalls. Under CSA Z96-22, Class 2 and Class 3 bib overalls must now have a retroreflective stripe circling each leg.

This wasn't just a random change; it was driven by safety data. Adding leg bands creates a more complete human silhouette, helping drivers recognize a person much faster than they would a disconnected, floating torso. The movement of the legs while walking also creates a "biomotion" effect that our eyes are hardwired to notice, especially in our peripheral vision. It’s a small tweak that makes a massive difference in preventing accidents by making workers more recognizable and predictable to drivers in complex, low-light environments.

How To Read a CSA Z96-22 Garment Label

Think of your garment's label as its safety passport. It’s a small tag, but it's packed with the critical information that proves your gear is compliant and right for the job. At first glance, the jumble of codes and numbers can look like a secret language, but learning to decode it is one of the most important safety checks you can perform before you even step on site.This little label is your guarantee that the apparel meets the demanding requirements of the CSA Z96-22 standard. It’s the final word on whether your gear can actually do its job of keeping you visible and safe. When you know how to read it, you can instantly verify compliance and spot any outdated, non-compliant, or unsuitable apparel before it becomes a problem.

The Key Components of the Label

Every single compliant garment will have a label that clearly shows a few key pieces of information. It's designed to be a quick-reference guide to the garment's specific safety features.

Here's what to look for and what it all means:

-

Standard Identification: The label has to say "CSA Z96-22" plain and simple. This tells you the garment was made and tested according to the most current Canadian standard for high-visibility safety apparel. If you see an older standard, like Z96-15, that gear may no longer be compliant with today's regulations.

-

Class and Level: You'll see a designation like "Class 2, Level 2" or "Class 3, Level 2." As we’ve covered, the Class number (1, 2, or 3) is all about the garment's overall visibility rating, based on how much background material it has and where it’s meant to be used. The Level number (1 or 2) tells you how well the retroreflective material performs, with Level 2 offering the highest reflectivity for night work or low-light conditions.

Identifying Special Protections

Beyond the basics, the label also tells you if the garment offers protection from other specific hazards, which is absolutely vital for anyone working in a multi-hazard environment.

The most common extra marking you'll see is "FR," which stands for flame-resistant. This is a non-negotiable for anyone working near potential flash fires, arc flashes, or other thermal hazards. A standard polyester vest can melt and cause horrific burns in one of those incidents, but proper FR-rated gear is designed to self-extinguish.

Crucial Safety Check: If your job involves any thermal risks, always confirm the "FR" designation on the label. A garment that is only CSA Z96-22 compliant, without that FR rating, offers zero protection against fire and can actually make an injury much, much worse.

For workers who need this kind of dual protection, a piece of gear like a premium FR long-sleeve shirt with Class 2 visibility is a perfect example of how these safety standards come together. The label on a shirt like that would clearly show it complies with both CSA Z96-22 and the relevant FR standards, like NFPA 2112.

A Practical Label Example

Let’s pull it all together and break down a typical label you might find inside a hi-vis jacket:

CSA Z96-22

Class 2, Level 2

FR - ASTM F1506

In just a few seconds, this label tells you everything you need to know:

- It meets the current high-visibility standard.

- It’s built for moderate-risk environments near traffic (Class 2).

- It uses high-performance retroreflective tape for night use (Level 2).

- It's also flame-resistant and compliant with a key arc flash standard (FR - ASTM F1506).

By taking a moment to read and understand this label, you can get to work with the confidence that your gear is giving you exactly the protection you need.

How Canadian and US Standards Work Together

For any team working across North America, juggling different safety standards can feel like a headache. The good news is that when it comes to high-visibility gear, the standards in Canada and the US are designed to cooperate, not conflict.

Think of it like this: while they're closely aligned, "harmonized" doesn't mean "identical." A garment that's compliant with the American ANSI/ISEA 107 standard is definitely going to make a worker visible. But that same piece of gear might be missing a crucial detail for a Canadian job site, like the mandatory "X" pattern on the back required by CSA Z96-22.

The Goal of Technical Harmony

The latest CSA Z96-2022 standard is a huge step forward in getting everyone on the same page globally. It was built from the ground up to achieve technical harmony with the two other major players: ANSI/ISEA 107 in the United States and the international ISO 20471 standard. You can learn more about this cooperative effort on the ANSI blog.

This alignment is a massive win for safety managers and procurement teams. It means you can source high-quality gear knowing it’s built on globally respected safety principles. You still need to double-check for the specific Canadian details, but the foundation is solid.

Key Takeaway: While CSA Z96-22, ANSI/ISEA 107, and ISO 20471 all share the same goal of protecting workers, the CSA standard has unique Canadian requirements. To be fully compliant on a job site in Canada, your gear absolutely must meet the specific criteria of Z96-22.

Critical Differences to Remember

The real devil is in the details, and with hi-vis gear, that almost always means the retroreflective striping patterns. These aren't just for show; they are critical visual cues designed specifically for Canadian work environments.

Here are the key distinctions you can't afford to miss:

- The Back 'X' Pattern: This is the most famous CSA Z96-22 requirement and it’s a non-negotiable in Canada. It's not mandatory under ANSI/ISEA 107, but its purpose here is brilliant: it instantly tells you if a worker is facing towards you or away from you.

- Limb Bands: CSA Z96-22 has very specific rules for how arm and leg bands must be configured on Class 3 garments. The goal is to create a clear human silhouette from a distance, and these rules can differ from the ANSI requirements.

- Flame-Resistance Integration: Things get even more specific when you need to combine high-visibility with flame resistance. Both Canada and the US have their own robust standards for FR clothing. For dual-hazard environments, you have to ensure a garment meets both the visibility rules of CSA Z96-22 and the appropriate FR standards, like those we cover in our guide to NFPA 2112.

At the end of the day, it's simple. If the work is happening in Canada, the CSA Z96-22 standard is the law of the land. Checking that your team’s gear meets these specific Canadian rules isn't just about compliance—it's about ensuring they have the best possible protection on the job.

Taking Care of Your High-Visibility Gear

Your high-vis apparel isn't just another part of the uniform; it’s a frontline piece of life-saving equipment. But like any tool on the job site, it's only effective if you keep it in good shape. Over time, all that dirt, grime, and grease—plus improper washing—can completely kill the properties that make your gear visible in the first place, putting you right back in harm's way.

Proper maintenance is about more than just looking clean; it’s about making sure your gear still meets the tough demands of CSA Z96-22. When the fluorescent background material gets dirty, it loses its pop. When retroreflective tape gets covered in muck or damaged by harsh laundry chemicals, it can no longer bounce light back. It’s simple: a clean garment is a visible garment.

To keep your hi-vis gear working as intended, you need a solid care routine. Think about how a good preventive maintenance schedule template helps keep machinery running smoothly; the same logic applies to inspecting and cleaning your safety apparel. A little routine care goes a long way in catching problems before they turn into serious safety risks.

Washing and Drying Done Right

How you wash your gear makes a massive difference. The first rule is always to check the manufacturer's care tag, since every garment is a bit different. But a few universal rules apply to pretty much all high-visibility apparel.

- Go with Mild Detergent: Harsh soaps can actually break down the fluorescent pigments and strip the microscopic glass beads off the reflective tape.

- No Bleach or Fabric Softeners: Chlorine bleach will permanently murder the fluorescent colour. Fabric softeners are just as bad, leaving a film on the retroreflective tape that stops it from working.

- Wash in Cold Water: Hot water can shrink the garment and might even weaken the adhesive holding some types of reflective tape in place.

- Hang to Dry: This is the gentlest method, hands down. If you have to use a machine, tumble dry on the lowest heat setting to avoid cooking the materials.

While industrial laundering is an option for the really grimy stuff, it’s tough on the gear. Each cycle adds to the wear and tear, and manufacturers usually state a maximum number of washes a garment can handle before it's time for it to be retired.

Crucial Tip: Always wash your hi-vis gear separately from your heavily soiled work clothes. This stops grease and oil from other garments from transferring over and leaving permanent, visibility-killing stains.

Knowing When to Retire Your Gear

Even with the best care in the world, every piece of high-visibility clothing has a shelf life. Wearing faded, damaged, or worn-out gear is just as dangerous as wearing nothing at all. You need to give your apparel a quick inspection before each shift and replace it the second you spot any of these red flags:

- Faded Background Colour: If the bright yellow, orange, or red material looks dull and doesn't stand out anymore, its job is done. Time for a new one.

- Damaged Retroreflective Tape: Look for cracks, peeling bits, or entire sections of the silver tape that are missing. Any damage here seriously cuts down its ability to reflect light at night.

- Visible Stains: Permanent stains from asphalt, oil, or chemicals create dark patches that completely compromise your visibility.

- Tears or Rips: Any physical damage means the garment no longer has the required surface area of visible material, making it non-compliant and unsafe.

At the end of the day, your visibility is your first line of defence on any job site. Treating your gear with respect and knowing when to replace it aren't just good habits—they are critical safety practices that uphold the entire purpose of the CSA Z96-22 standard.

Common Questions About CSA Z96-22

Even with a good handle on the classes and materials, plenty of practical questions about the CSA Z96-22 standard come up on the job site. This section is all about tackling the most common ones we hear from workers and safety managers, giving you clear, direct answers to help you stay compliant and safe.

Think of this as your go-to guide for sorting out those nagging points of confusion. From old gear to new logos, getting these details right is the difference between an okay safety program and a truly effective one.

Is My Old CSA Z96-15 Gear Still Compliant?

This is easily one of the most frequent questions we get, and the answer isn't a simple yes or no. A lot depends on your provincial jurisdiction and your own company’s safety policies. While some regions may have offered a transition period when the new standard rolled out, the best practice is always to adopt the latest standard for maximum safety.

The CSA Z96-22 standard brought in some important updates that older Z96-15 garments just don't have. For example, the mandatory leg striping on Class 2 bib overalls is a new requirement. Federally regulated workplaces are now bound by the updated Canada Occupational Health and Safety Regulations, which point directly to the 2022 standard.

The safest and most reliable move? Upgrade your gear. Always double-check with your local regulatory body, but switching to Z96-22 compliant apparel ensures you're both protected and playing by the current rules.

Can I Put A Company Logo On My Hi-Vis Vest?

Yes, you can add logos, but you have to follow some very strict rules. The standard is incredibly specific about the minimum surface area of high-visibility background material needed for each garment class. Any additions—logos, patches, embroidery—can't cover up so much of this material that the garment drops below that minimum requirement.

This makes logo placement absolutely critical. You need to position them strategically in areas that don't block the fluorescent background or the retroreflective striping.

Important Consideration: To make sure you don't accidentally void a garment's compliance, it's always best to work with a supplier who knows their stuff. They can make sure any customization is applied in a way that fully respects the integrity and safety requirements of the CSA Z96-22 standard.

What Is The Difference Between Fluorescent And Retroreflective Material?

Getting this distinction is the key to understanding how your gear keeps you visible 24/7. The easiest way to think about it is a simple division between daytime and nighttime protection.

-

Fluorescent Material: This is the bright yellow-green or orange background of your vest or jacket. It’s designed for daytime and low-light conditions like dawn and dusk. The material reacts with the sun's invisible UV rays, making it pop with exceptional brightness so you stand out against almost any background.

-

Retroreflective Material: These are the silver stripes on your apparel. They’re built for nighttime and don't create their own light. Instead, they’re covered in tiny glass beads or prisms that bounce light from a source, like a car's headlights, directly back to the driver’s eyes. This makes you instantly visible in the dark.

A fully compliant garment has to use both types of materials. It's this combination that guarantees the wearer is conspicuous at all hours and in any lighting condition.

Do I Need Flame-Resistant High-Visibility Clothing?

This comes down entirely to a hazard assessment of your specific work environment. If your job exposes you to potential arc flash, flash fire, or other thermal hazards, then you absolutely need dual-compliant FR hi-vis gear. This is standard issue for workers in industries like oil and gas, electrical utilities, and industrial refining.

Standard hi-vis gear is usually made from synthetic materials like polyester. In a fire, these materials can melt and drip, causing terrible burns. FR hi-vis garments, on the other hand, are made from materials that will self-extinguish and won't melt when they're exposed to flames.

This dual-compliant gear is a lifeline. It provides critical protection against thermal hazards while also meeting the tough visibility requirements of CSA Z96-22. For workers in these environments, it isn't an optional upgrade—it's an essential piece of life-saving equipment.

At Refinery Work Wear Canada, we provide a comprehensive range of dual-compliant FR and high-visibility apparel to keep your team safe and seen in any environment. Explore our collection of CSA Z96-22 compliant gear today. Visit us at https://canada.refineryworkwear.com.