When you work in high-risk industries, the clothes on your back can be the deciding factor between a near miss and a life-changing injury. That’s where NFPA 2112 comes in.

This isn't just another safety acronym; it's the North American standard that outlines the minimum performance requirements for flame-resistant (FR) clothing designed to protect against flash fires. Think of compliant gear less like fireproof armour and more like a crucial safety tool that buys you precious, life-saving seconds to escape a thermal hazard.

Your Guide to NFPA 2112 Protection

In environments like refineries or chemical plants, standard workwear made of cotton or polyester can be a massive liability. If exposed to a flash fire, these materials can ignite and continue to burn, or worse, melt directly onto your skin, drastically compounding the severity of an injury. This is the exact problem NFPA 2112 was designed to prevent.

The National Fire Protection Association (NFPA) is a global non-profit dedicated to eliminating death, injury, and loss from fire and related hazards. While NFPA 2112 focuses on FR garments, the organization sets standards for all sorts of safety measures, including emergency exit signage requirements. The core mission of this specific standard is simple: ensure your personal protective equipment (PPE) never becomes part of the problem.

Who Needs NFPA 2112 Compliant Gear?

This standard is a must-have for any industrial worker who could face a flash fire. A flash fire is a sudden, incredibly intense blaze caused when a flammable substance mixes with air and ignites. These events are terrifyingly fast—often lasting three seconds or less—but they unleash an immense amount of heat.

Industries where this level of protection is absolutely vital include:

- Oil and Gas: Workers across upstream, midstream, and downstream operations are constantly around flammable gases and vapours.

- Chemical Manufacturing: Handling volatile chemicals means an accidental release could easily lead to a flash fire.

- Refineries and Petrochemical Plants: Processing crude oil involves highly flammable materials under extreme pressure and temperature.

- Pharmaceutical Production: Certain manufacturing processes use flammable solvents that carry a significant risk.

The Fundamental Safety Principle

The philosophy driving NFPA 2112 is both simple and powerful: your clothing should not contribute to your injury. To earn certification, fabrics and finished garments go through a battery of tough tests to prove they won't melt, drip, or keep burning once the flame source is gone.

The standard’s primary goal is to minimize burn injury severity, giving the wearer critical escape time. It ensures that the protective clothing itself self-extinguishes, providing a stable thermal barrier instead of becoming fuel for the fire.

By setting these strict performance criteria, NFPA 2112 gives safety managers and workers a reliable benchmark. It takes the guesswork out of safety, moving beyond vague claims of being "flame resistant" to a verifiable, third-party certified system of protection you can trust.

For a deeper dive into how these garments work, you can explore our ultimate guide to flame-resistant (FR) clothing for more details. This foundation of verified safety is what makes compliant gear an indispensable part of any modern industrial safety program.

The Critical Tests Behind NFPA 2112 Certification

Getting a garment certified to NFPA 2112 isn't about slapping a label on it. It’s a hard-won credential, backed by a battery of intense, standardized tests that push fabrics and finished clothing to their absolute limits.

Each test is designed to mimic the brutal, instantaneous violence of a flash fire. This ensures every single part of a garment—from the main fabric right down to the sewing thread and zippers—acts as a reliable shield against thermal hazards. We’re moving beyond promises on a tag to verifiable proof of protection.

At the very heart of this process is the ASTM F1930 manikin test. It's widely seen as the gold standard for judging how an entire garment will hold up when things go wrong, giving a much clearer picture than just testing a small swatch of fabric.

The Instrumented Manikin Test Explained

Picture a life-sized manikin, but one that's been kitted out with over 100 heat sensors positioned all over its body. These sensors are there to measure the exact amount of heat energy that would get through the clothing and transfer to a person's skin.

A complete, off-the-shelf garment is dressed onto this high-tech manikin. Then, it's engulfed in a controlled, all-encompassing flash fire.

The fire itself lasts for a precise three seconds—a duration chosen to simulate the short, incredibly intense nature of a real-world industrial flash fire. Throughout this exposure, the sensors are constantly feeding back heat data. This information is then crunched to calculate the most critical metric of all: the total predicted body burn, specifically the percentage of second- and third-degree burns a worker would likely suffer.

The pass/fail line for the ASTM F1930 test is incredibly strict. To earn NFPA 2112 certification, a garment must result in a predicted total body burn of 50% or less. This number wasn't picked out of a hat; it’s directly tied to a massive increase in survival rates from real thermal incidents.

This single, powerful test forces the garment to perform as a complete system. Every seam, pocket, and closure is held accountable, because in a real emergency, every single detail matters.

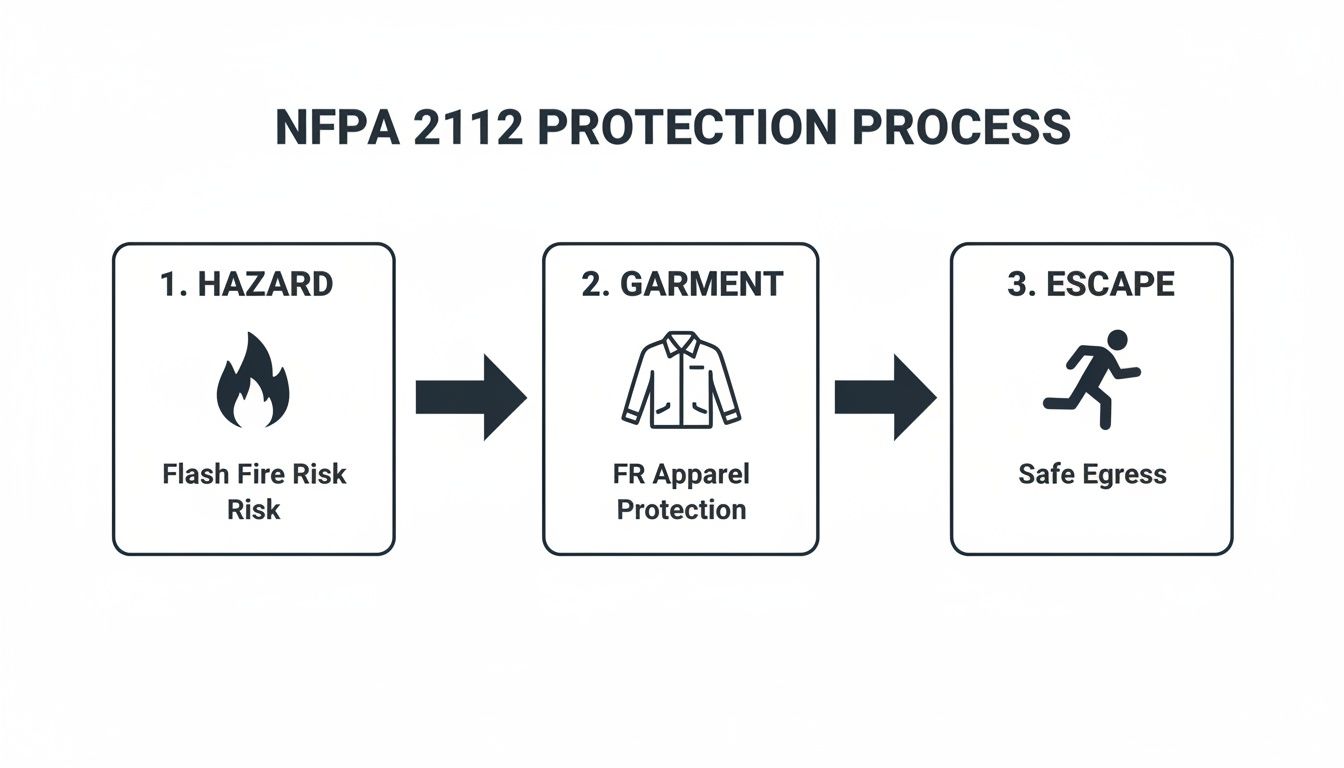

This infographic shows just how vital an NFPA 2112 garment is when a worker has to react to a sudden hazard.

It perfectly illustrates how certified apparel creates that critical buffer between a person and the danger, buying them the precious seconds needed to get to safety.

Component-Level Testing Requirements

While the manikin test looks at the big picture, NFPA 2112 also demands that every individual piece of the garment passes its own set of tough lab tests. This makes sure the fundamental building blocks are sound before they’re even sewn together.

These tests include:

- Vertical Flammability Test (ASTM D6413): A piece of the fabric is hit with a direct flame for 12 seconds. To pass, it has to stop burning on its own within two seconds of the flame being removed, and the char length (the scorched, damaged part) must be minimal. This is the test that proves the fabric won't keep burning and add fuel to the fire.

- Heat Transfer Performance (HTP) Test: This test measures how well the fabric insulates against both direct flame (convective) and radiant heat. It gives the material a rating that tells you how long a worker has before the heat penetrating the fabric would cause a second-degree burn.

- Thermal Shrinkage Resistance: Fabric samples get baked in a high-heat oven to see how much they shrink. If a fabric shrinks too much, it’s an automatic fail. Excessive shrinkage can cause the garment to pull tight and away from the body, opening up gaps and exposing skin directly to the heat.

These component-level checks are non-negotiable. The best-designed garment in the world is useless if its fabric ignites, its seams burst, or its zippers melt shut. The integrity of high-quality flame-resistant jackets, for example, depends on every single component passing these individual tests.

The Importance of Third-Party Certification

Meeting the NFPA 2112 standard isn't based on a manufacturer's word. It's about independent, verifiable proof.

This is why having a third-party organization, like UL (Underwriters Laboratories), conduct the testing is so crucial. It guarantees the results are unbiased and the tests are done the exact same way, every time.

When you see that certification mark on a garment's label, it's not just a logo. It’s your confirmation that the clothing has survived the full gauntlet of NFPA 2112 tests. That seal of approval is your guarantee that you're getting a verified, life-saving layer of protection.

How to Read FR Garment Labels and Verify Protection

Not all flame-resistant clothing is created equal. The real story of a garment's protective power is told by the small label sewn inside, and learning how to read it is a critical skill for any safety manager or worker. Think of that label as your first line of defence against gear that isn't up to the job.

The most important thing to understand is the massive difference between a manufacturer claiming their gear is compliant versus having it formally certified by an independent third party. One is just a statement; the other is documented proof.

That certification mark is like a seal of approval on a critical piece of equipment. It’s your unbiased guarantee that the garment has been put through the wringer and passed every single test required by the NFPA 2112 standard. When seconds count, that verification is what ensures life-saving performance.

Differentiating Compliance from Certification

People often use "compliant" and "certified" as if they mean the same thing, but in the world of PPE, they are worlds apart. Knowing the difference helps you spot legitimate FR gear and steer clear of products that only offer a false sense of security.

-

Compliant: This is when a manufacturer says their product meets the NFPA 2112 standard. The catch? This claim might be based on their own internal tests, with no outside oversight.

-

Certified: This means an accredited, independent organization like UL (Underwriters Laboratories) has rigorously tested the garment and confirms it meets every single requirement of the NFPA 2112 standard.

The presence of a third-party certification mark is non-negotiable. It is the only way to be certain that a garment's design, materials, and construction have been independently scrutinized and found to provide the specified level of protection against flash fire.

Without that mark, you're just taking a manufacturer at their word. With certified gear, you have proof.

What to Look for on an NFPA 2112 Label

A proper NFPA 2112 label has specific information that confirms its certification. When you're inspecting a garment—whether it's an FR jacket or a pair of flame-resistant coveralls—make sure you can find these key elements:

- Statement of Compliance: The label must clearly state that the garment meets the requirements of "NFPA 2112."

- Third-Party Certification Mark: This is the most crucial part. Look for the official logo of the certifying body, like the UL mark.

- Manufacturer Information: The name or details of the manufacturer should be on the label.

- Garment Identification: A style number or tracking code that ties the specific garment back to its official certification file.

- Fibre Content and Care Instructions: Details on the fabric blend and, just as importantly, how to wash it properly to maintain its FR properties.

This detailed labelling is all part of an ongoing quality control system. In fact, there's a push within the standards committee to require annual recertification for any products that have been modified. For Canadian suppliers, this means planning for yearly verification if they switch fabrics or change the construction. This is a big deal, as it directly impacts procurement budgets and inventory cycles for companies managing large FR programs. This diligent process ensures that the protection you rely on today remains just as trustworthy tomorrow.

Understanding How NFPA 2112 and CSA Z462 Work Together

In the world of industrial safety, one of the most common points of confusion is the relationship between NFPA 2112 and CSA Z462. It's a critical distinction to get right. While both standards demand flame-resistant (FR) clothing, they are designed to protect against two fundamentally different thermal hazards.

Assuming one standard automatically covers the other is a dangerous—and surprisingly common—mistake.

Let's break it down with an analogy. A flash fire is like being caught in a widespread, engulfing wave of heat. An arc flash, on the other hand, is like getting hit with a concentrated, explosive bolt of energy. NFPA 2112 is engineered to handle the wave; CSA Z462 is built for the bolt. Both require FR protection, but the "how" and "why" are entirely distinct.

The Core Hazard Distinction

The primary mission of NFPA 2112 is to protect workers from flash fires. These are brief but incredibly intense fires fuelled by airborne flammable vapours, gases, or dust. The real danger here is widespread thermal exposure over the entire body. Garments are tested to make sure they won't ignite, melt, or keep burning after the initial flash, giving a worker those precious seconds needed to escape.

In contrast, CSA Z462, Canada's Standard for Electrical Safety in the Workplace, is all about arc flash hazards. An arc flash is a violent, explosive release of energy from an electrical fault. It creates an insanely hot plasma blast, hurls molten metal projectiles, and produces blinding light. The main protective metric here is the Arc Thermal Performance Value (ATPV), which measures how well a fabric can insulate against this concentrated burst of energy.

The key takeaway is this: NFPA 2112 is about surviving a widespread, short-duration fire. CSA Z462 is about surviving a focused, explosive electrical event. The physics and the required fabric properties are completely different.

How Testing Reflects the Hazard

You can really see the different purposes of these standards in their required tests. This is why a garment certified for one hazard isn't automatically good for the other.

-

NFPA 2112 Testing Focus: The main event is the ASTM F1930 manikin test. A full garment is put on a sensor-covered manikin and exposed to a three-second simulated flash fire. The test then predicts the total body burn percentage. The goal is to prove the clothing provides systemic, full-body protection and won’t act as fuel itself.

-

CSA Z462 Testing Focus: This standard relies heavily on the ASTM F1959 test to figure out a fabric's ATPV, measured in calories per square centimetre (cal/cm²). This test zaps a small fabric panel with an electric arc to find the exact point where enough heat transfers through to cause a second-degree burn.

A garment can have fantastic flash fire resistance but a low ATPV, making it totally unsafe for arc flash work. Likewise, a high-ATPV garment might never have gone through the full manikin test required for NFPA 2112 certification.

NFPA 2112 vs CSA Z462 at a Glance

To make it even clearer, let's put the two standards side-by-side. This table highlights the core differences every safety manager should know.

| Attribute | NFPA 2112 (Flash Fire) | CSA Z462 (Electrical Safety) |

|---|---|---|

| Primary Hazard | Short-duration, widespread fire from airborne flammable fuels. | Explosive energy release from an electrical fault (arc flash). |

| Testing Focus | Full-garment manikin test (ASTM F1930) to predict total body burn. | Fabric-level arc testing (ASTM F1959) to determine Arc Rating (ATPV). |

| Common Industries | Oil & gas, petrochemical, chemical manufacturing, pharmaceuticals. | Electrical utilities, industrial electricians, maintenance in any facility with energized equipment. |

Seeing them laid out like this makes it obvious they are designed to solve very different problems, even though they both fall under the "FR clothing" umbrella.

The Rise of Dual-Hazard Protection

On many modern job sites, workers face multiple risks at the same time. Think of an electrician in a refinery or a maintenance technician in a chemical plant—they could easily be exposed to both electrical and flash fire hazards. This reality has pushed the industry to develop dual-certified garments.

These advanced garments are specifically engineered and tested to meet the requirements of both NFPA 2112 and a specific arc rating under standards like ASTM F1506. When you check the label, it will explicitly state its compliance with NFPA 2112 and list its ATPV rating.

This versatility is a game-changer, but it all starts with one non-negotiable step: a thorough hazard assessment. Before you even think about selecting FR clothing, you must identify every potential thermal hazard a worker might face on your site. For organizations needing to keep up with NFPA 2112 and other safety protocols, effective regulatory compliance training is crucial to ensure everyone understands their role in this process.

Ultimately, the specific risks on your site dictate the protection you need. Never guess.

Extending the Life of Your FR Garments with Proper Care

The special protective qualities of your NFPA 2112 clothing are built right into the fabric’s fibres. This isn't just a surface treatment. It means the flame-resistant properties won't wash out or wear away over time, which is a huge advantage.

But just because the protection is inherent doesn't make the garment invincible. How you care for your gear can seriously compromise its integrity and, when it matters most, your safety. Following the right maintenance routine is every bit as important as picking the right gear to begin with.

Laundering Do's and Don'ts

Washing your FR clothing the right way is the single best thing you can do to keep it in service longer and make sure it performs when you need it. The wrong laundering methods can weaken the fabric or, even worse, coat it with flammable residues.

Key Laundering Rules:

- Do wash FR garments on their own. Keeping them separate from your everyday clothes prevents cross-contamination from flammable materials or residues.

- Do turn your gear inside out before washing. This simple step helps protect the outer surface and any reflective striping from wear and tear.

- Don't use chlorine bleach, ever. Bleach attacks and breaks down the FR polymers in the fabric, destroying its protective structure.

- Don't use fabric softeners or starch. These products leave behind a flammable coating on the fibres that can easily ignite and keep burning.

Think of fabric softener like a thin, flammable layer of paint on your shield—it completely defeats the purpose of wearing FR gear. When in doubt, always follow the specific instructions on the garment’s tag.

The Critical Importance of Proper Repairs

A rip, tear, or hole in your FR clothing isn't just a cosmetic problem; it's a critical failure point in your thermal barrier. To maintain full NFPA 2112 protection, any and all repairs must be done with materials that are also flame-resistant.

Using standard cotton thread or grabbing an ordinary patch is a dangerous mistake. In a flash fire, that non-FR thread will ignite and burn away, causing the seam to split wide open and expose your skin directly to the heat.

Every single repair material—patches, thread, zippers, you name it—must be flame-resistant and meet the same tough standards as the original garment. This is the only way to ensure you have a continuous, unbroken layer of protection.

If you're ever unsure about how to properly repair a garment, it's always safer to talk to your supplier or just retire it from service. The integrity of your PPE, including specialized items like FR bib overalls, depends on every single component doing its job.

Knowing When to Retire a Garment

Even the best-maintained FR garment has a limited lifespan. Recognizing when it's time to take a piece of clothing out of rotation is a crucial safety call. It's time to retire a garment when it's:

- Damaged beyond repair: Think large tears, widespread holes, or frayed seams that can't be safely and completely mended.

- Contaminated: Soiled with flammable substances like oils, greases, or chemicals that you can't get out in the wash.

- Worn out: The fabric is noticeably thin, threadbare, or has lost its structural integrity.

Get into the habit of inspecting your gear before every single shift—it's non-negotiable. Trying to squeeze a little more life out of a worn-out garment is a gamble you can't afford to take.

A Few Common Questions About NFPA 2112

When you're dealing with safety standards, a few questions always seem to pop up. The world of NFPA 2112 is no exception. We've gathered some of the most common queries we hear from safety managers and the folks on the ground to give you direct, clear answers.

Think of this as a quick way to solidify your understanding of flash fire protection so you can manage your FR clothing program with total confidence. Let’s jump right in.

Can't I Just Use 100% Cotton Clothing Instead?

This is a common myth, and a dangerous one. Some people think that since 100% cotton doesn't melt and drip like synthetic fabrics, it's a safe, cheap alternative to FR clothing. That couldn't be further from the truth.

While it's true cotton won't melt, it's highly flammable. If it's exposed to a flash fire, standard cotton will ignite and keep on burning, basically turning your clothes into a fuel source right against your skin.

This is exactly the kind of disaster NFPA 2112 is built to prevent. Certified FR garments are specifically designed to self-extinguish within two seconds after the flame is gone. This simple feature stops the thermal injury from getting worse and buys the wearer precious seconds to escape. Untreated cotton offers zero of this protection and will make a burn injury significantly worse.

Is NFPA 2112 Compliance Mandatory for Every Industry?

No, the requirement for NFPA 2112 gear isn't a blanket law for everyone. It all comes down to a site-specific hazard assessment, which is mandated by provincial Occupational Health and Safety (OHS) regulations here in Canada.

If your workplace hazard analysis points to a risk of flash fire—a common threat in oil and gas, chemical processing, and refining—then providing compliant FR clothing becomes a mandatory part of your company's due diligence. It’s the employer’s job to do that assessment and put the right protective gear in place.

The bottom line is this: if a flash fire hazard exists at your site, employers have a legal duty to provide PPE that meets the recognized industry standard for that threat. When it comes to flash fires, that standard is NFPA 2112.

How Do We Layer FR Garments for Extra Protection?

Layering FR clothing is a great way to boost your thermal protection, but it has to be done the right way. There's one golden rule here: every single layer you wear, right down to your skin, must be flame-resistant. That includes your t-shirts, long underwear, and anything else underneath.

Putting on a non-FR item, like a regular cotton t-shirt, under your certified FR coverall is a huge mistake. If a flash fire happens, that inner cotton layer can ignite and burn directly on your skin, trapped by the outer FR garment. It completely defeats the purpose of the expensive gear you’re wearing on top.

For safe and effective layering, follow this simple system:

- Base Layer: Must be an FR-rated material. No exceptions.

- Mid-Layer: An FR shirt or hoodie works perfectly for extra warmth and protection.

- Outer Layer: This is your main FR coverall, jacket, or bib pants.

When every layer is FR, you create a system where each garment works together to insulate you from the intense heat. To get a better feel for how different pieces create a complete safety system, you can find more info on the various types of FR clothing and where they fit in. This ensures that staying warm and comfortable never comes at the cost of your safety.

At Refinery Work Wear Canada, we provide the certified NFPA 2112 compliant garments that serve as the backbone for any solid FR clothing program. Check out our lineup of proven, reliable FR workwear today at https://canada.refineryworkwear.com.