When you hear FR Coveralls, what comes to mind? For a lot of folks in high-risk Canadian industries, they're just part of the daily uniform. But these specialized garments are so much more than that—they're a critical lifeline.

They're designed to self-extinguish when hit with flames or intense heat, which drastically cuts down the risk of severe burn injuries. Regular clothes, on the other hand, can ignite and keep burning, making a bad situation infinitely worse. That’s why in jobs with flash fire or arc flash hazards, FR coveralls are non-negotiable personal protective equipment (PPE).

What Are FR Coveralls and Why Are They Critical PPE?

Let’s think about it this way: standard cotton or polyester work clothes are like dry kindling near a spark. They’ll go up in flames in an instant and feed the fire.

Now, picture FR coveralls as specially treated wood. It’s built to resist catching fire in the first place, and if it does, it quickly snuffs itself out once the heat source is gone. This simple analogy gets to the heart of what flame-resistant workwear does. It's not about being fireproof; it's about buying you those precious seconds to escape a hazard before your own clothes add to the injury.

This self-extinguishing property is the game-changer. It’s what turns a simple uniform into a piece of life-saving equipment. During a flash fire or an electric arc flash, the thermal blast is incredibly intense but very short. In that split second, FR coveralls are engineered to char instead of melting or igniting. This creates an insulating barrier that shields you from the worst of the heat.

A Non-Negotiable Safety Barrier

For workers in Canada's toughest sectors, this gear isn't a "nice-to-have." It's essential. The first step is always a thorough process of understanding workplace hazard identification. Once you know the risks, getting the right gear is paramount.

Just think about some of the high-risk environments where coveralls FR are standard issue:

- Oil and Gas: On drilling rigs, in refineries, and along pipelines, the risk of flash fires from flammable gases and liquids is a constant threat.

- Electrical Utilities: Linemen and technicians work right next to the danger of arc flashes, which can generate temperatures hotter than the sun's surface.

- Heavy Manufacturing: Welders, foundry workers, and chemical plant operators are surrounded by materials and processes that pose serious thermal hazards.

In these jobs, FR coveralls are not just a dress code—they are a fundamental component of a comprehensive safety system designed to prevent life-altering injuries.

The growing focus on workplace safety isn't just talk; it's reflected in the numbers. The industrial protective clothing market is on track to grow from $22.4 billion in 2024 to $24.06 billion in 2025, a jump driven by stronger regulations and a greater awareness of safety. It really underscores just how vital proper PPE is for preventing accidents.

Ultimately, the goal of FR coveralls is to minimize injury, not to pretend risk doesn't exist. By giving workers a reliable barrier that won’t catch fire and burn, they provide a fighting chance to walk away from an incident that could have been devastating. For a deeper dive into the science and standards behind it all, check out our ultimate guide to flame-resistant (FR) clothing.

Decoding Canadian Safety Standards for FR Clothing

Trying to make sense of the safety standards on your FR gear can feel like you're reading another language. But when it comes to FR coveralls, knowing what those codes and numbers mean is absolutely critical for your safety. In Canada, a few key standards work in tandem to guarantee your gear offers real, proven protection against specific hazards on the job.

Think of these standards as a recipe for safety. Each one is a tested, crucial ingredient needed to cook up a garment that will actually protect you when things go wrong. On any Canadian worksite with electrical hazards, the most important recipe book is CSA Z462.

This standard is all about workplace electrical safety, built from the ground up to protect workers from the brutal, life-altering damage of an arc flash. It’s more than just a gear recommendation; it’s a whole framework for analyzing hazards, which in turn tells you exactly what level of protection you need to be wearing.

Understanding Arc Flash Protection

The heart of arc flash protection is measured in something called calories per square centimetre (cal/cm²). It sounds super technical, but the idea behind it is pretty straightforward. It's simply a measure of how much heat energy a fabric can take before you'd likely get a second-degree burn through it.

The official rating that tells you this is the Arc Thermal Performance Value (ATPV). You'll find it printed right on the tag of any piece of arc-rated clothing.

An ATPV rating tells you the maximum blast of thermal energy the fabric can handle. For instance, a garment with a 12 cal/cm² rating is certified to shield you from an arc flash event that kicks out up to that much heat. Picking gear with a rating that meets or beats the potential hazard level on your site isn't just a good idea—it's non-negotiable.

This rating system is broken down into easy-to-understand categories. They used to be called Hazard Risk Categories (HRC), but now under CSA Z462, they're known as Arc Flash PPE Categories. This change makes it much simpler for everyone, from safety managers to the folks on the tools, to pick the right protective system.

- Category 1: Requires a minimum arc rating of 4 cal/cm².

- Category 2: Requires a minimum arc rating of 8 cal/cm².

- Category 3: Requires a minimum arc rating of 25 cal/cm².

- Category 4: Requires a minimum arc rating of 40 cal/cm².

Knowing your site's required category is the first step in choosing the right FR coveralls. Many of the most versatile options out there are built to meet Category 2 requirements, which makes them a solid choice for a huge range of electrical work. You can check out a wide variety of compliant FR bib overalls to find options that line up with your job's specific arc rating needs.

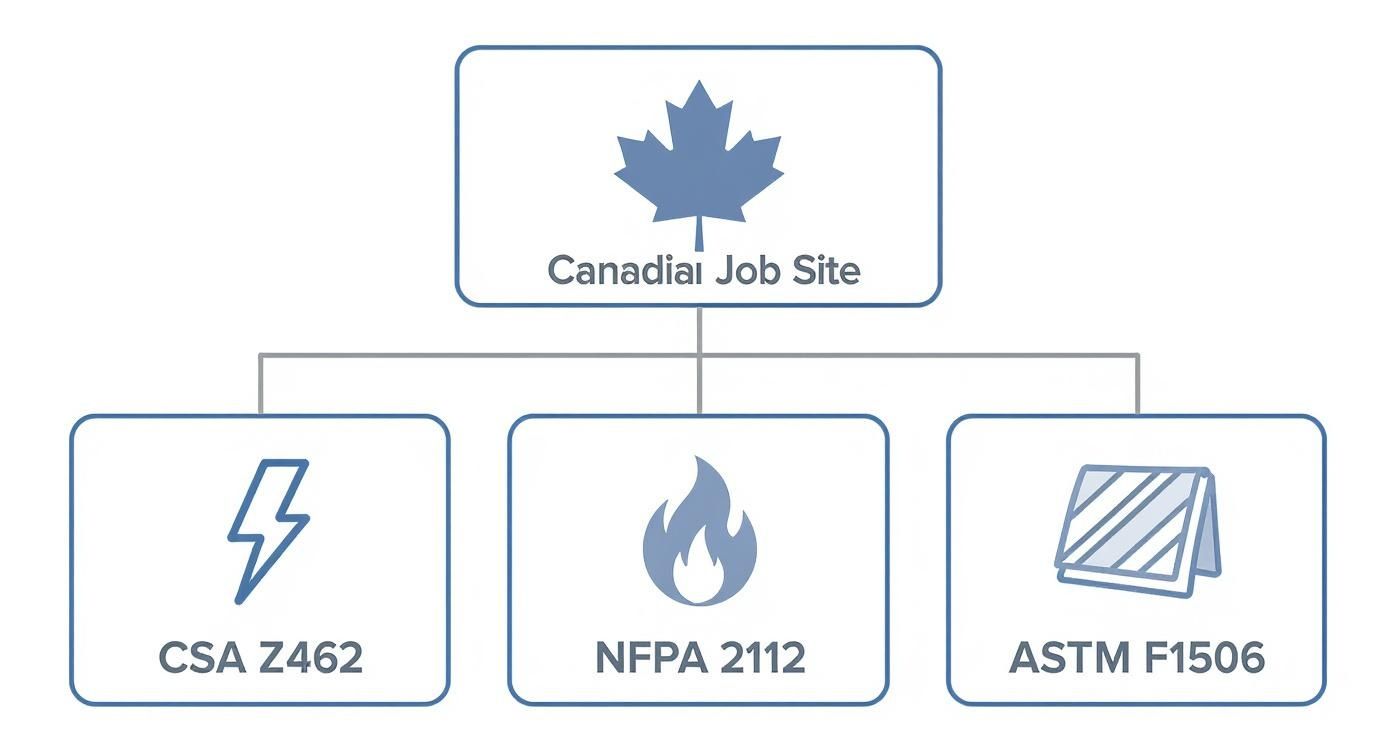

Key North American Standards on Canadian Job Sites

While CSA Z462 is the go-to standard for electrical safety here in Canada, you'll almost always see two other major North American standards listed on your garment tags. They cover different, but just as serious, hazards and are often required by employers right across the country.

Here's a quick look at how these core standards fit together.

Key FR and Arc Flash Safety Standards at a Glance

| Standard | Governing Body | Primary Hazard Protection | Key Requirement or Rating |

|---|---|---|---|

| CSA Z462 | Canadian Standards Association (CSA) Group | Arc Flash | Defines Arc Flash PPE Categories (1-4) based on cal/cm² ratings. |

| NFPA 2112 | National Fire Protection Association (NFPA) | Flash Fire | Garment must result in 50% or less total body burn in a 3-second test. |

| ASTM F1506 | American Society for Testing and Materials | Fabric performance for Arc Flash | Sets the base test method for determining a fabric's ATPV (cal/cm²). |

Let's dig a little deeper into what those other two mean for you.

NFPA 2112 for Flash Fire Protection

The National Fire Protection Association's NFPA 2112 standard is the gold standard for protecting against flash fires. This is a huge risk in industries like oil and gas or petrochemicals, where a sudden ignition of flammable vapour can create a fast-moving wall of fire.

To get the NFPA 2112 stamp of approval, a garment goes through an intense 3-second thermal mannequin test. This test simulates a flash fire and measures how much of the body would be burned. A garment only passes if the predicted total body burn is 50% or less.

ASTM F1506 for Arc Flash Fabric Testing

Think of the American Society for Testing and Materials' ASTM F1506 as the foundation that the other standards are built on. It's a performance specification that outlines the minimum requirements for any fabric used in arc flash protective clothing. For a garment to even be considered for CSA Z462 or NFPA 70E (the US electrical safety standard) certification, its fabric has to pass the tests in ASTM F1506 first.

This standard is what ensures the fabric won't melt, drip, or catch on fire and keep burning after being hit by an electric arc. It’s the foundational test that gives us that all-important ATPV rating.

Ultimately, these standards all work together. A quality pair of FR coveralls for a Canadian worker facing multiple hazards will often have tags showing it complies with CSA Z462, NFPA 2112, and ASTM F1506. Seeing all three gives you the confidence that you're protected from every angle.

Choosing the Right Fabric for Your Work Environment

Picking the right pair of FR coveralls is about a lot more than just the colour or the logo on the chest. The fabric is the real technology, the critical layer standing between you and a serious thermal hazard.

Think of it like buying tires for your truck. You wouldn't put slick racing tires on a rig you're taking up a muddy logging road in Northern B.C. In the same way, the best FR fabric is always the one matched to your specific job site, striking the right balance between protection, comfort, and durability.

The two main families of FR fabric you’ll run into are treated fabrics and inherent fibres. Each one gets to flame resistance in a completely different way.

Treated vs. Inherent FR Fabrics

Treated fabrics, which are usually cotton or tough cotton-nylon blends, are everywhere for good reason. These materials get their flame-resistant properties from a chemical treatment that bonds directly to the fibres. On the job, they’re known for being comfortable, breathable, and generally easier on the budget upfront.

On the other hand, inherent FR fabrics are made from fibres that are flame-resistant from the inside out, right down to their molecular DNA. The protection is baked right in and can never be washed out or worn away. Materials like Nomex® and Modacrylic are in this camp, offering lifetime protection, though you'll often see a higher price tag.

The real difference comes down to permanence. With treated fabrics, the FR shield can weaken over time if you wash them improperly—using bleach or fabric softener is a big no-no. With inherent fibres, that protection is there for good, lasting the entire life of the garment.

Comparing Common FR Fabric Options

Let’s pull back the curtain on the most common materials you'll find on a garment tag and what they actually mean for you day-to-day.

- Treated Cotton/Nylon Blends (e.g., UltraSoft®): This is a true workhorse fabric. It gives you the comfort of cotton but adds the rugged abrasion resistance of nylon. It's a fantastic all-around choice for many industries because it nails that sweet spot of protection, durability, and cost. A perfect example is the popular Portwest Bizflame FR Coverall, which gives you solid multi-hazard protection you can count on.

- Inherent Aramid Fibres (e.g., Nomex®): Aramids are incredibly tough and heat-resistant. They won't melt, drip, or catch fire. That makes them the top-shelf choice for high-risk jobs in oil and gas or firefighting where you simply can't compromise on protection.

- Inherent Modacrylic Blends: Modacrylic fibres are often blended with other materials like cotton or aramid. This helps make the garment more comfortable and affordable while keeping those essential inherent FR properties. They offer a great middle-ground, giving you lasting protection with a much softer feel.

This diagram breaks down how Canadian job sites operate under a hierarchy of standards. It starts with the broad CSA Z462 for electrical safety, then drills down to NFPA 2112 for flash fire protection and ASTM F1506 for arc flash fabric testing. It’s a great visual reminder that true safety means meeting the specific standard for every hazard you face.

Beyond the Fabric: Construction Details That Matter

Even the most advanced FR fabric is useless if the garment itself falls apart at the seams. How your FR coveralls are put together is every bit as important as the material they're made from. You need to look for the small but vital details that tell you a garment is built for the real world.

One of the most critical elements is the stitching. If it's sewn with standard polyester or nylon thread, those seams will melt at high temperatures, causing the whole garment to fail and exposing your skin to danger. Proper FR garments must be sewn with heat-resistant aramid thread.

You also want to look for reinforced construction. Check the high-stress points—the crotch, shoulders, and pocket corners—for triple-stitched seams or bar-tacking. These little details are what ensure your coveralls can handle all the pulling, stretching, and scraping of a hard day's work without ever compromising their protective integrity.

How to Find the Perfect Fit and Essential Features

Finding the right pair of FR coveralls isn't like grabbing a new pair of jeans off the rack. Here, the fit is a critical piece of your safety gear, not just a matter of looking good. If a garment is too loose, it can easily snag on machinery. If it’s too tight, it can dangerously restrict your movement in an emergency and put stress on the seams, which could compromise the entire protective barrier.

Think of your FR coveralls as a second skin, one that's been specifically engineered for your safety. It has to give you a full range of motion—squatting, reaching, climbing—without pulling tight across your back or shoulders. But it also can't be so baggy that the cuffs or extra fabric get tangled in equipment. The perfect fit is one you can forget you’re even wearing.

Getting the Measurements Right

The secret to a great fit is starting with accurate numbers. Don't just guess your size or go by what you wear in regular street clothes. Grab a soft measuring tape and get the real measurements for your chest, waist, and inseam.

A classic mistake people make is forgetting to account for the clothes they’ll wear underneath. You’ll almost always have a base layer on, and in the thick of a Canadian winter, you might be wearing heavier FR-rated layers.

Always take your measurements while wearing the underlayers you'd typically have on during a workday. This simple step ensures your coveralls will fit comfortably over your other gear without feeling restrictive when you’re actually on the job.

Once you have your measurements, check them against the manufacturer’s specific sizing chart. Don't ever assume a "Large" from one brand is the same as a "Large" from another—sizing can be all over the map.

The Importance of Gender-Specific Designs

The days of a one-size-fits-all approach to workwear are thankfully over. Women's bodies are built differently than men's, and a "unisex" or men's coverall often creates a poor, and frankly unsafe, fit for female workers. Ill-fitting gear is more than just uncomfortable; it's a serious hazard waiting to happen.

For example, a garment that’s too wide in the shoulders but too narrow in the hips for a woman can create dangerous bunching around the waist and seriously limit mobility. Women-specific FR coveralls are designed with these differences in mind from the ground up, offering a fit that is both safer and way more functional.

- Improved Mobility: Contoured fits that account for different shoulder-to-waist and waist-to-hip ratios allow for a much better, more natural range of motion.

- Enhanced Safety: A proper fit gets rid of the excess fabric that could get caught in machinery and ensures the garment sits correctly on the body to do its job.

- Greater Comfort: The job is tough enough without fighting your own clothes all day. A comfortable fit reduces fatigue and helps you stay focused on the task at hand.

Must-Have Functional Features

Beyond the fit, the features built into your coveralls can make a huge difference in your day-to-day efficiency and safety. These aren't just bells and whistles; they're practical tools designed for the real demands of industrial work.

Here are some of the most important features to look for:

- Two-Way Zippers: A heavy-duty brass or aramid zipper that opens from both the top and bottom is a game-changer for convenience and ventilation.

- Pass-Through Pockets: These clever openings let you access the pockets of the pants you’re wearing underneath without having to unzip your entire coverall.

- Reinforced Knees: For any job that has you kneeling, double-layered or reinforced knees will drastically extend the life of your garment.

- Action Back: Look for pleats in the fabric across the upper back. This "action back" gives you extra room to move your arms forward and overhead without the whole garment pulling tight.

- Storm Flaps: A flap of fabric covering the front zipper is crucial for keeping out wind, sparks, and debris.

- Customization Options: Adding company logos or names helps with identification and builds a sense of team unity. For specialized needs, explore options for custom embroidery to make sure your crew's gear is perfectly suited to them.

Maintaining and Inspecting Your FR Coveralls

Your FR coveralls are a critical piece of safety equipment, but their protective qualities are only as good as their condition. Think of it like the brakes on your truck; they need regular care and inspection to perform reliably when you need them most. Proper maintenance isn't just about keeping your gear clean—it's about preserving the life-saving technology woven into every fibre.

Neglecting proper laundering can actively destroy the flame-resistant properties of your garment, turning a vital safety tool into a potential hazard. This is especially true for treated FR fabrics, where harsh chemicals can strip away the protective finish, leaving you exposed.

Proper Laundering Rules for FR Garments

Forget how you wash your regular clothes. Everyday laundry products can be disastrous for FR fabrics. Bleach, for example, is a major enemy—its oxidizers can chemically break down the FR treatment, rendering your coveralls useless in a fire.

Similarly, fabric softeners and starch are strictly off-limits. They do more than just soften the material; they coat the fibres with a flammable residue. This residue acts as a fuel source during a thermal event, completely negating the garment's self-extinguishing capabilities.

Follow these simple rules to keep your FR coveralls safe and effective:

- Wash Separately: Always wash your FR gear on its own. This prevents cross-contamination from flammable residues left behind by your everyday clothes.

- Use Mild Detergent: Stick to a simple home laundry detergent. Avoid bleach, fabric softeners, starch, or any products containing hydrogen peroxide.

- Turn Inside Out: This simple step helps protect the outer surface and any high-visibility striping from abrasion during the wash cycle.

- Use Warm Water: Wash in warm water (up to 60°C or 140°F) to effectively remove soils and contaminants without damaging the fabric.

- Dry on Low Heat: Tumble dry on a low setting or, even better, hang to dry. Excessive heat can cause the garment to shrink and may damage certain FR fibres over time.

A common myth is that you can "wash out" the protection from inherent FR fabrics like Nomex®. While the protection itself is permanent, flammable contaminants like oil or grease that aren't properly washed out can still ignite. Cleanliness is always a key part of FR safety.

Your Pre-Shift Inspection Checklist

Just as crucial as proper washing is a diligent visual inspection before every single shift. This routine takes less than a minute but it’s your best defence against wearing compromised gear. You are the final quality check.

Grab your coveralls and look them over in a well-lit area. Pay close attention to high-stress points like the knees, elbows, and seams, as these are often the first places to show wear.

What to Look For:

- Rips, Tears, or Holes: Even a small opening is a big problem. It can allow heat and flame to reach your skin, completely bypassing the FR protection.

- Thinning Fabric: Hold the garment up to a light source. If you can easily see light passing through areas like the knees or seat, the fabric has worn thin and must be retired.

- Flammable Contamination: Check for any stains from oil, grease, fuel, or other flammable substances that didn't wash out. These can act as fuel in a fire.

- Damaged Closures: Ensure all zippers, snaps, and buttons function correctly. A broken zipper can create a dangerous gap in your protective barrier.

- Reflective Striping Condition: If your coveralls have high-visibility tape, check for excessive cracking or peeling that could reduce your visibility. You can learn more about why well-maintained reflective striping is another vital layer of safety.

Knowing when to retire a garment is non-negotiable. If you find any of these critical warning signs during your inspection, that piece of gear must be taken out of service immediately. When it comes to your safety, there is absolutely no room for doubt.

Building an Effective FR Layering System

True protection from a flash fire or arc flash doesn't just stop with your outerwear. A single pair of FR coveralls is a great start, but when you're in a high-risk environment, a smart layering system is what really keeps you safe.

Think of it like dressing for a nasty Canadian winter. One big jacket is okay, but we all know that multiple, well-chosen layers provide far better insulation and let you adapt to changing conditions. It’s the same idea with your FR gear.

The logic behind FR layering is simple: every additional FR garment adds to the total thermal insulation. This builds a more effective barrier between your skin and the terrifying heat of a thermal event. Even the air trapped between each layer acts as an extra insulator, slowing down how quickly that intense heat can reach you.

This combined protection is measured by adding the Arc Thermal Performance Value (ATPV) of each piece of clothing. For example, if you wear an 8 cal/cm² FR shirt under a 12 cal/cm² FR coverall, you don't just get 12 cal protection. You get a complete system with a rating that’s actually much higher than 20 cal/cm².

Why Every Single Layer Must Be FR

This is non-negotiable. Every piece of clothing you put on, from your t-shirt right out to your jacket, has to be flame-resistant. Throwing on a regular polyester shirt or a cotton-poly blend under your FR coveralls is one of the most dangerous mistakes you can make on the job.

In an arc flash or flash fire, non-FR synthetic fabrics like polyester and nylon will instantly melt right onto your skin. This causes horrific secondary burns. Your coveralls could perform perfectly, but that melting underlayer can still cause life-altering injuries. This is why safety standards are absolutely clear: no meltable fibres can be worn next to the skin.

Remember, your entire layering system is only as strong as its weakest link. Make sure every garment is either certified FR or, for lower-risk tasks, made from non-melting natural fibres like 100% cotton.

Taking the Guesswork Out of Safety with Managed Uniform Programs

For any company, making sure every single worker has the right gear—and that it’s all properly maintained and layered correctly—can be a logistical headache. This is where a managed uniform program becomes a game-changer. It’s not just about buying uniforms; it's about outsourcing your entire PPE safety and compliance process.

A managed program brings some serious advantages to the table:

- Guaranteed Compliance: The provider handles the details, ensuring every employee gets gear that meets the exact CSA, NFPA, and ASTM standards their job requires. No more guesswork for you.

- Specialized Laundering: They manage the complex washing and care needed to maintain FR integrity, preventing the kind of damage that improper home laundering can cause.

- Automated Lifecycle Management: The program tracks the age and condition of every garment, automatically swapping out worn or damaged items before they ever become a hazard.

- Simplified Logistics: It centralizes everything—ordering, distribution, repairs, and replacements—freeing up your safety managers to focus on their actual jobs, not chasing down coveralls.

As Canadian industries like manufacturing and construction keep growing, the demand for reliable PPE solutions is only going up. The global coveralls market is expected to see a Compound Annual Growth Rate of around 6% from 2025 through 2033, driven by exactly this need. A managed program helps companies meet this demand head-on, ensuring every worker is protected, every single day. You can learn more about the trends shaping the coveralls market and see why these services are becoming so essential.

Common Questions We Hear About FR Coveralls

Even after you've narrowed down your choices, it's normal to have a few more questions about FR coveralls. Getting the right answers is key to making sure you and your crew are properly protected on the job. Let's dig into some of the most common things workers and safety managers ask us.

Are Flame Resistant and Flame Retardant the Same Thing?

This is a big one, and while people often use the terms interchangeably, there’s a crucial technical difference.

"Flame resistant" (FR) fabrics are made from fibres that are inherently non-flammable right down to their molecular structure. Think of materials like Nomex®—the protection is baked right into the fabric's DNA. It won't wash out or wear away over time.

"Flame retardant," on the other hand, usually refers to fabrics like cotton or cotton blends that have been chemically treated to self-extinguish when hit with a flame. Both types of garments have to pass the same tough safety standards, but for long-haul durability, inherently FR fabrics usually come out on top. The most important thing is to always check that the garment is certified to the specific standard your job site demands, like NFPA 2112 or CSA Z462.

Can I Wear a Polyester Shirt Under My FR Coveralls?

No. Absolutely not. This is one of the most critical—and sometimes overlooked—rules in FR safety.

If you're caught in a flash fire or arc flash, regular synthetic fabrics like polyester, nylon, or spandex will melt directly onto your skin. This can cause horrific secondary burns, even if your coveralls do their job perfectly.

It's a dangerous mistake to think the outer layer is all that matters. Your underlayers are just as critical. Heat from an incident can transfer right through your coveralls, and a melting fabric underneath completely defeats the purpose of your primary PPE.

Always wear an FR-rated base layer or a non-melting natural fibre like 100% cotton or wool under your FR coveralls. For any job with a serious thermal hazard, a complete FR layering system is the only truly safe way to go.

How Do I Know When to Replace My FR Coveralls?

Knowing when to retire a piece of gear is a non-negotiable part of staying safe. You have to take your coveralls out of service immediately if you spot any of these issues during your pre-shift check:

- Holes or Tears: Any opening that can't be properly patched with FR-compliant materials is a breach in your protective barrier. Simple as that.

- Worn-Thin Fabric: If the material at the knees, elbows, or seat is visibly thin and threadbare, its protective qualities have been seriously compromised.

- Permanent Contamination: Stains from flammable stuff like oil, grease, or chemicals that won't wash out are a major ignition risk.

- Damaged Hardware: A broken zipper, busted snap, or any closure that won't fasten securely leaves a dangerous gap in your protection.

Get in the habit of inspecting your gear before every single shift. If you have any doubt about the condition of your FR coveralls, play it safe and replace them. It's not worth the risk.

At Refinery Work Wear Canada, our mission is to equip Canadian workers with certified, top-quality FR apparel that stands up to the toughest safety standards. Take a look at our wide selection of FR coveralls and build a safety system you can truly depend on.

Shop Our Full Collection of FR Coveralls at Refinery Work Wear Canada