NFPA 70E is the go-to standard for electrical safety in Canadian workplaces and beyond. It lays out how to assess risk, prevent arc flash events, choose the right PPE and establish safe work procedures.

Why NFPA 70E Matters

By setting down clear, practical rules, NFPA 70E drives down arc flash and arc blast injuries. It fills the gap between installation codes and personal protection, making daily electrical work far safer.

Key benefits include:

- Eliminate Hazards through risk assessments and engineering controls

- Define Approach Boundaries and safe work conditions

- Match FR Clothing and PPE to calculated incident-energy levels

- Mandate Training and qualification standards for all electrical tasks

- Document Everything—procedures, labels and incident records—to prove compliance

This guide offers a high-level preview of each chapter:

- Definitions and key terms explained with real-world analogies

- Employer obligations and the essentials of a written safety program

- Risk assessment and PPE-selection workflows

- Labeling, documentation and permit system best practices

- Training requirements, record keeping and audit readiness

- Actionable tips for CSA/NFPA-compliant FR clothing and footwear

Guide Structure At A Glance

We’ve organised this guide to build your understanding step by step—from core concepts to advanced compliance strategies. Each chapter builds on the last, so you’ll always know where you are in the journey.

Summary Of NFPA 70E Key Elements

Below is a quick-glance table of the most critical NFPA 70E provisions every electrical worker and safety manager should know before diving deeper.

| Element | Description |

|---|---|

| Arc Flash Analysis | Evaluate incident energy levels to determine PPE requirements |

| PPE Selection | Match flame-resistant gear to the calculated hazard rating |

| Safe Work Procedures | Apply lockout/tagout, permits and set approach boundaries |

| Training Requirements | Identify qualified personnel and deliver targeted training |

| Documentation And Labeling | Maintain hazard labels, records and traceable audit trails |

Keep this table close as you move into detailed explanations in the following chapters.

Next Steps In This Guide

In the upcoming sections, you’ll discover:

- Core definitions with down-to-earth analogies

- Step-by-step incident-energy calculations

- Employer duties and how to craft a robust safety programme

- Labelling standards and documentation workflows

- Training outlines, record-keeping tips and audit prep

- Practical advice on picking CSA-approved FR clothing and footwear

For gear and PPE recommendations, check out our Complete Guide to Safety Supplies.

This guide’s chapters include definitions, requirements, tables and annex guidance packed with examples. We’ll reference key tables—like 130.4(D) for approach boundaries and incident-energy thresholds—to anchor safe work practices.

Real-world case studies and clear metaphors will demystify arc flash and arc blast hazards. You’ll walk away with practical takeaways to set up or audit your electrical safety programme.

Later chapters drill into tips for selecting CSA-approved FR clothing and footwear tailored to Canadian worksites. Each section wraps up with checklists and action steps so you can apply NFPA 70E on the job.

Keep this overview handy as you roll out your electrical safety programme, and stay focused on the key elements that protect lives.

Understanding Key Concepts

NFPA 70E is all about keeping people safe from electrical danger. It lays out clear terminology for identifying risks—so everyone’s on the same page.

An arc flash is like seeing a camera’s flash in reverse. Instead of light hitting you, the equipment throws out a blast of energy that can burn anything in its path.

An arc blast, on the other hand, feels like a sudden shove of scorching air. It can hurl tools, shatter limbs of metal and wreak havoc on hearing and eyesight.

When we talk about energized work, we mean any job near live parts above 50 V, where shock or arc flash is a genuine threat. NFPA 70E tries to minimise these tasks or, if unavoidable, demands strict controls.

Incident energy is the heat dose at your working distance, measured in cal/cm². That figure tells you exactly which flame-resistant clothing and PPE will stand up to the hazard.

Core Definitions

Arc flash and arc blast are siblings but very different events. One cooks you; the other blasts you.

Energized work kicks in when you can’t establish an electrically safe work condition. That’s when an energized work permit becomes non-negotiable.

Incident energy isn’t a rough guess—it’s calculated using fault current, clearing times and equipment specs. This gives your risk assessment rock-solid grounding.

“Matching PPE to your incident energy calculation is what actually protects people,” says a safety engineer with over 15 years on the tools.

Key Terms at a Glance:

- Arc Flash: Electrical discharge causing intense heat and burn risk

- Arc Blast: Pressure wave that can injure and propel debris

- Energized Work: Live-parts tasks above 50 V requiring permits

- Incident Energy: Thermal energy at your working distance (cal/cm²)

Practical Connections

These definitions aren’t just jargon—they feed straight into your safe work plan. A lines technician, for example, uses incident energy values to pick the right flame-resistant gear every time.

Imagine a panel upgrade at a midstream facility. The team calculated 8 cal/cm² of incident energy and selected Category 2 PPE. Result? A smooth swap with no surprises.

Four Steps to Hazard Control:

- Identify the electrical hazard and see if de-energization is possible.

- Calculate incident energy per NFPA 70E formulas.

- Choose PPE rated for the calculated energy level.

- Document values and post warning labels for future reference.

Applying In The Field

An energized work permit formalises approval for live tasks, listing hazard levels, required PPE and safe boundaries. It’s your checklist before touching a live circuit.

At a Canadian refinery, a maintenance crew used a permit to swap breakers without shutting down production. Clad in 10 cal/cm² gear, they finished on schedule—and incident-free.

This method turns technical terms into real-world action. A clear table pairs incident energy numbers with PPE categories, so there’s no guesswork.

For in-depth guidance on flame-resistant fabrics and certifications, see our guide on NFPA 2112 compliance.

Key Takeaway

Matching incident energy to the correct PPE is the backbone of NFPA 70E compliance—and it’s what truly keeps workers safe.

Best Practices to Remember:

- Always measure incident energy before any live work.

- Use conservative clearing times for breakers older than five years.

- Train staff on reading labels and permit details.

- Store PPE in a clean, dry area and inspect before each use.

Connect To Regulations

Terms like energized work tie directly into legal duties under provincial safety codes. For example, Ontario’s Electrical Safety Code references NFPA 70E definitions when outlining live work permit requirements.

Using consistent language in your safety programmes and regulatory documents smooths out compliance audits. Inspectors focus on hazard controls rather than debating terminology.

With this foundation in place, you’re ready to explore employer obligations, risk assessments and CSA-approved PPE. The chapters ahead will guide you through building a complete NFPA 70E safety programme and choosing the right FR clothing and footwear for Canadian workplaces.

NFPA 70E Requirements In California

Cal/OSHA has sharpened its focus on electrical safety, nudging employers to weave NFPA 70E principles into everyday practices. Gone are the days of guess-work when handling live circuits—now you need clear rules, permits and protective gear.

Key Employer Obligations

- Qualified Electrical Worker designations make sure only trained staff open panels or tackle energized equipment.

- Written Electrical Safety Programmes spell out hazard assessments, step-by-step procedures and required PPE.

- Energized Work Permits are mandatory for any live tasks on circuits ≥ 50 V, cutting down on on-the-fly approvals.

- PPE Usage rules match flame-resistant clothing to calculated incident energy levels.

This mix of administrative checks and hands-on controls follows NFPA 70E Table 130.4(D) approach boundaries.

Institutional Examples

Take the University of California and Lawrence Berkeley National Laboratory: both have woven NFPA 70E (2018 edition) into their policy handbooks and training schedules. In the same vein, the City of Ventura now requires its maintenance crews and contractors to stay compliant.

These programmes typically include:

- Written safety procedures

- Energized work permits

- Role-based and refresher training

“A structured permit system and consistent training reduce electrical incidents significantly,” notes a Cal/OSHA safety advisor.

Since the 2010s, public agencies and large employers across California have adopted NFPA 70E-aligned practices, covering everything from worker designations to arc-flash calculations.

Discover more insights about NFPA 70E adoption on e-hazard.com.

Required Program Elements

| Element | Description |

|---|---|

| Approach Boundaries | Defines restricted and limited boundaries (Table 130.4(D)) |

| Hazard Analysis | Arc-flash incident energy calculations |

| Permit Systems | Written approvals for all live work |

| Training Curricula | Baseline and refresher modules for Qualified staff |

Regular audits and updates keep these elements in sync with evolving electrical systems.

Tips For Implementation

- Conduct a gap analysis against NFPA 70E clauses to spot missing controls.

- Weave NFPA 70E language into existing safety policies for consistency.

- Place incident energy labels on panels to guide PPE selection at a glance.

- Run annual drills that simulate permit workflows and emergency responses.

Follow these steps—designation, documentation and training—to mitigate electrical risks.

Common Mistakes To Avoid

- Skipping approach boundary updates and underestimating arc-flash hazards

- Relying on outdated PPE categories instead of real incident energy data

- Forgetting to review your safety programme after system changes

- Treating energized work permits as mere paperwork instead of safety checkpoints

A clear process, backed by documentation and training, is your best defence against on-site electrical incidents.

Next Steps For Compliance

- Bring in certified safety consultants to audit your programme

- Refresh training materials to match the latest NFPA 70E edition

- Use arc-flash analysis software for accurate labels and records

- Schedule quarterly reviews of safety files and incident logs

True compliance means continuous updates and active engagement at every level.

Building A Safety Culture

When safety becomes second nature, NFPA 70E requirements live in every toolbox talk. Encourage technicians to share feedback on permit clarity and PPE comfort. Peer-led sessions on arc-flash risks spark real conversations in the field.

Celebrate milestones—zero-incident days, clean audit reports—to keep morale high. Regularly showcase success stories to remind everyone why these rules matter.

Risk Assessment And PPE Selection

Tackling arc-flash hazards is a bit like suiting up for battle: you need to gauge the threat before picking the right armour. In NFPA 70E, that means blending precise calculations with grounded PPE decisions.

Start by pinpointing fault currents and clearing times for each piece of gear. From there, you’ll feed those numbers into incident energy formulas—no guesswork allowed.

Step-By-Step Hazard Analysis

First, gather nameplate data and calculate the maximum available fault current at your work distance. Next, nail down protective-device clearing times for the incident energy equation.

- Collect equipment identifiers and fault-current readings.

- Note the protective device type and its trip/clearing time.

- Plug values into IEEE 1584 or NFPA 70E equations.

- Cross-check results with software or a manual sanity check.

Accurate nameplate info and up-to-date maintenance records are non-negotiable. When gear’s aged or data’s fuzzy, err on the side of caution with conservative values.

PPE Selection Guidelines

Matching calculated energy to your protective ensemble is straightforward once you have the numbers. Here’s a quick rundown:

- Category 0: FR shirt and pants for < 1.2 cal/cm²

- Category 1: Arc-rated outerwear up to 4 cal/cm²

- Category 2: Gear rated for 8 cal/cm² exposures

- Category 3: Systems handling 25 cal/cm² events

- Category 4: Multi-layer ensembles above 40 cal/cm²

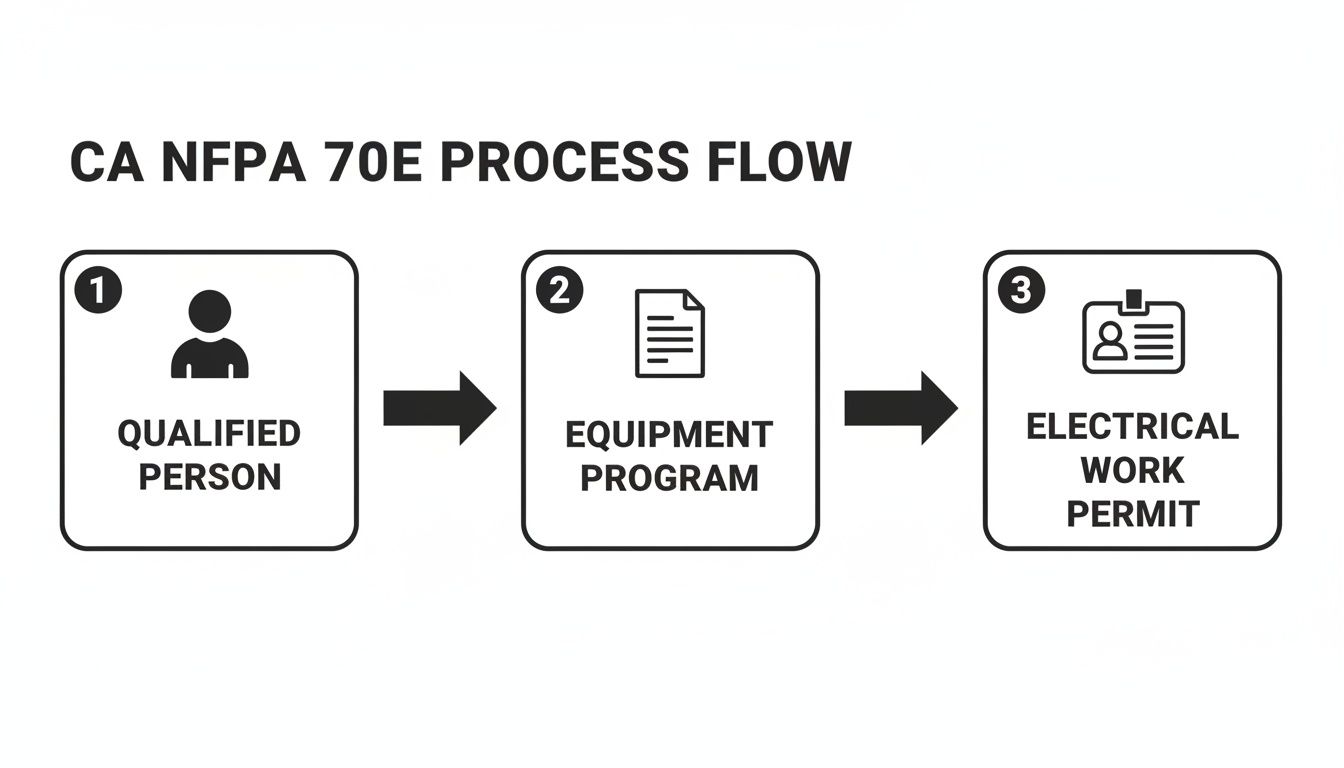

With your PPE choices locked in, it’s time to visualise the compliance journey.

This diagram highlights qualified designations, safety programmes and energized-work permits—the three pillars of a robust arc-flash prevention plan.

Equipment Labeling And De-Energization Planning

Clear labels are your first line of defence. Slap incident energy values on panels so teams know at a glance what they’re up against—and plan to de-energize whenever you can.

- Verify upstream device specs to confirm clearing times.

- Use arc-flash software to auto-generate label templates.

- Apply durable signage with energy values and approach boundaries.

- Review labels anytime you swap protective devices or reconfigure the system.

Pair these tags with digital records to keep warnings accurate and current. You might also find our guide on choosing cut-resistant gloves to complement your arc-flash PPE ensemble helpful: Cut-Resistant Gloves Guide.

Software Tools And Verification

Arc-flash analysis platforms eliminate tedious manual entries by auto-calculating fault currents and clearing times. Most will even spit out printable reports and label stickers, speeding up your compliance workflow.

Key Calculation Factors

Incident energy isn’t just fault current times clearing time. Your working distance, busbar dimensions, conductor material and enclosure depth all tweak the final numbers. Always double-check those variables before signing off.

Example Case Study

For instance, in a California plant, a transformer check returned 6.5 cal/cm² at 18 inches. The engineers specified Category 2 PPE, issued a written permit and de-energized the feeder—all long before anyone touched a terminal. No surprises, no second-guessing.

Incident Energy Categories And PPE Requirements

Below is a quick comparison of incident energy thresholds and the PPE you need for each category:

Incident Energy Categories And PPE Requirements

| Incident Energy Threshold | PPE Category | FR Clothing Requirement |

|---|---|---|

| < 1.2 cal/cm² | 0 | FR shirt and pants |

| 1.2–4 cal/cm² | 1 | Arc-rated jacket + hood |

| 4–8 cal/cm² | 2 | Arc-rated suit (8 cal/cm²) |

| 8–25 cal/cm² | 3 | Arc-rated suit (25 cal/cm²) |

| > 25 cal/cm² | 4 | Multi-layer FR gear |

This table helps you match calculated energy levels with the right protective clothing, turning arc-flash analysis into a clear, repeatable process.

Training And Employer Obligations

Under NFPA 70E, your organisation carries the lead on electrical safety training and record-keeping. It’s more than ticking boxes—you’re building a culture where everyone knows the rules and sticks to them.

Start by drafting a clear, written Electrical Safety Program. Spell out who trains whom and when, and put an energized-work permit system in place for any live tasks. This framework removes guesswork and aligns perfectly with Cal/OSHA’s safety expectations.

Defining Qualified Workers

Qualified workers aren’t just a title—they’ve proven they can spot and control electrical hazards safely. Unqualified staff get general awareness training but stay clear of live work at all times.

“Only those with up-to-date training and hands-on assessments should tackle live circuits,” notes a seasoned safety advisor.

Key distinctions include:

- Training Depth: Detailed modules cover lockout/tagout, arc-flash hazard analysis and hands-on drills.

- Experience Requirements: Practicals signed off by mentors, plus documented assessment records.

- Refresh Cycle: Formal refresher courses every 3 years or whenever standards shift.

Learn more about our managed FR uniform and work-boot program to support qualified staff in staying prepared.

Tracking Training Data

California State University, Los Angeles rolled out an Electrical Safety Program in 2017 that mirrors NFPA 70E. Their playbook covers:

- Defining Qualified Personnel

- Baseline training for qualified vs. unqualified workers

- Permits for any live work on circuits ≥ 50 V

- PPE requirements and restricted approach distances (3 ft. 6 in.)

By translating Cal/OSHA rules into measurable controls, they track:

- Number of Qualified Workers trained

- Energized-work permits issued annually

- PPE inventory levels

For a deep dive, review the California State University Electrical Safety Program.

Record types and retention periods often follow this template:

| Record Type | Key Details | Retention Period |

|---|---|---|

| Training Completion Logs | Employee name, date, modules covered | 5 years |

| Permit Issuance Records | Permit number, scope, approval signatures | 5 years |

| PPE Inventory Registers | Item codes, quantities, issue dates | Until replacement |

Best Practices For Audit Readiness

- Check every employee file with a simple training-completion and permit checklist.

- Keep scanned certificates and permit forms backed up in secure cloud storage.

- Run quarterly internal audits to spot gaps before inspectors do.

- Update modules whenever new equipment or standards arrive.

Robust training programmes can cut electrical incidents by over 30%, according to internal safety metrics.

Pair instructor-led sessions with hands-on workshops so teams get comfortable with live-work permits and PPE selection. A disciplined record-keeping routine meets NFPA 70E—and makes audits a breeze.

Operational Benefits And Compliance

A solid training regime under NFPA 70E does more than satisfy regulators. It fosters a proactive safety mindset, boosts team confidence and can slash lost-time incidents by up to 25%.

Inspectors often praise companies that maintain neat training files and permit logs. Clear documentation translates into fewer questions and zero surprises during audits.

To get started:

- Map out roles and core competencies.

- Use sample checklists for training dates, permit approvals and PPE inspections.

- Integrate simple record-keeping templates into your safety management system.

- Review and tweak your training matrix as equipment or standards evolve.

By embedding these practices, your organisation not only stays compliant with NFPA 70E and Cal/OSHA but also keeps operations humming without unplanned downtime. Begin building your audit-ready training programme today and watch safety—and productivity—soar.

Implement Compliance Programs And Choose FR Clothing

Creating a successful NFPA 70E compliance programme isn’t a one-off checklist. It’s a living framework where policies, inspections and training become part of the daily rhythm.

Canadian workplaces rely on CSA-approved gear to meet safety codes and cut arc flash hazards. That starts with a clear FR clothing policy outlining how to choose, care for and retire each garment.

Begin with daily pre-work PPE checks during toolbox talks. A quick scan for tears or worn seams can stop a small defect from turning into a major risk.

Next, build a vendor audit template that measures each supplier against CSA Z462 and NFPA 70E. Focus on:

- Fabric Arc Rating: Verify the ATPV at the correct working distance

- Garment Weight: Balance protection with comfort and breathability

- Colourfastness: Ensure stripes and logos stay vivid through multiple washes

Imagine a field inspection form that instantly highlights seam fraying or illegible labels. With that in hand, safety managers can compare vendors and record every finding with confidence.

Evaluating Vendors And Garment Inspections

A structured vendor audit removes guesswork. Use a simple five-point scale to rate:

- Delivery consistency

- Accuracy of certification documents

- Availability of fit sessions and user training

Then, tackle garment inspections step by step:

- Check stitching and seam integrity for signs of wear

- Confirm labels remain readable under site lighting

- Test FR fabrics against 12 cal/cm² arc flash ratings

Regular inspections not only protect the crew—they build trust in the PPE programme.

Writing FR Clothing Policies

Your policy should form the backbone of your safety system. It needs to specify:

-

Inspection schedules for each garment type

-

Approved laundering methods (no bleach or fabric softeners)

-

End-of-life triggers for replacement

-

Replace garments after 50 wash cycles if the material shows thinning

-

Withdraw any item with over 10 percent seam damage

-

Archive retired garments for long-term degradation analysis

“Clear FR clothing policies reduce confusion and keep workers safe,” says a seasoned safety manager.

This level of detail keeps your programme aligned with CSA Z96 high-visibility striping and NFPA 70E PPE rules, giving everyone a clear reference point.

Integrating Daily PPE Inspections

Embedding FR checks into daily routines makes safety second nature. Use pre-work inspection cards that cover:

- Garment condition (rips, holes, frays)

- Proper fit and sizing

- Label legibility

Numbered checklists simplify training for new hires and refresher sessions. Tick the boxes, sign off, and you’ve got audit-ready records.

Vendor-led training sessions help workers spot wear issues before they become hazards. Keep all training and inspection logs in one central system so you can track trends and improvements over time.

| Garment Type | Inspection Interval | Replacement Cycle |

|---|---|---|

| Coveralls | Monthly | Every 12 months |

| Jackets | Monthly | Every 18 months |

| Shirts & Pants | Quarterly | Every 24 months |

For deeper insight on selecting FR garments and footwear, check out our ultimate guide to flame-resistant clothing in our The Ultimate Guide to Flame-Resistant Clothing.

A CSA-aligned compliance programme does more than meet regulations—it cuts downtime, limits risk and, above all, protects lives. By auditing vendors, crafting clear policies and weaving inspections into daily routines, you build a safer, more accountable workplace. Continuous reviews and policy updates will keep your programme sharp as standards evolve.

Frequently Asked Questions

What Is The Difference Between An Arc Flash And An Arc Blast?

An arc flash is essentially an electrical fireball. It unleashes intense heat—enough to ignite clothing or cause severe burns—and a brilliant flash of light that can damage eyesight.

By contrast, an arc blast is all about pressure. Imagine a shockwave powerful enough to hurl tools across the room and damage your hearing. In short, arc flashes burn you; arc blasts throw you.

When Should Equipment Be De-Energized Versus Using A Live-Work Permit?

Whenever you can, go for an electrically safe work condition—that means de-energizing the equipment before starting.

Live-work permits come into play only when shutting down systems would halt critical operations. Before any live task, you must:

- De-energize for all new installations or maintenance where it’s feasible

- Use a live-work permit for unavoidable hot-work on essential circuits

- Secure documented approval from a qualified person

How Do I Interpret Incident Energy Limits?

Incident energy is measured in cal/cm². Think of it as the minimum thermal load your PPE must withstand.

- Anything above 1.2 cal/cm²? You need arc-rated gear.

- Below that threshold? Standard PPE may suffice, but always follow your company’s safety procedure.

What Are Best Practices For Long-Term PPE Management?

Your PPE is only as good as your inspection routine. Before every shift:

- Visually check for rips, tears or burn spots.

- Note any contamination from oils or chemicals.

- Log each inspection in a central record.

Rotate and replace garments as soon as you spot damage or hit the manufacturer’s wash-cycle limit. A tight record-keeping habit keeps everyone safer.

Selecting Approach Boundaries

Approach boundaries set your no-go lines around live electrical parts. They keep you clear of both shock and arc-flash zones. NFPA 70E Table 130.4(D) spells out two key distances based on voltage:

- Limited Boundary: Entry requires basic PPE and caution

- Restricted Boundary: Full arc-rated gear mandatory

Always re-verify approach boundaries after equipment modifications or maintenance. That simple double-check can save lives.

How Should I Handle Unusual Work Scenarios?

No two jobs are identical. If you run into an oddball situation:

- Conduct a focused risk assessment.

- Bring in a qualified electrician or safety officer.

- When in doubt, plan for de-energization or escalate for higher-level approval.

Keep this checklist handy on every site to guide split-second decisions.

—

Refinery Work Wear Canada Shop Now