When you picture a hard hat, you're probably thinking of the standard cap-style version. But there's another key player in head protection: the full-brim hard hat. This is the one with a continuous, 360-degree brim that wraps all the way around the shell. It's that all-around edge that gives it a serious advantage over its cap-style cousins, offering far more protection from sun, rain, and falling debris. For many job sites, it's the first and best line of defence.

Understanding Your First Line of Defence

Don't just think of a full-brim hard hat as another piece of gear to check off a list. See it for what it really is: your personal shield on the job site. Its role goes way beyond just stopping a direct hit to the top of your head. This piece of PPE is a cornerstone of a worker's daily kit, especially when you're out in the elements where hazards can come from any and every direction.

That defining feature—the 360-degree brim—basically acts like a personal, mobile roof over your head. This is what gives it a crucial leg up on standard designs by guarding your face, neck, and ears from multiple threats at once.

The Advantage of Full Coverage

This all-around coverage delivers some real-world benefits that make a huge difference in a worker's safety and confidence. For starters, that wide brim is brilliant at channelling rainwater away from your collar, keeping you drier and maintaining clear vision when the weather turns nasty.

On bright, sunny days, it provides a ton of shade. This significantly cuts down the risk of sunburn and heat stress on sensitive spots like the back of your neck and your ears, which are completely exposed with a cap-style hat.

On top of that, the all-around edge helps deflect smaller falling objects, sparks, or chemical splashes, guiding them away from your face and body. In a dynamic work environment, that kind of multi-faceted protection is invaluable.

A hard hat is your most important piece of personal protective equipment. The full brim design expands its defensive capabilities, turning it from a simple impact shield into a comprehensive barrier against common environmental hazards.

It’s important to see how full-brim hard hats fit into the bigger picture of your overall safety protocol. For a great overview of how they work with other gear, you can check out this list of essential construction site safety equipment.

By exploring the full range of head protection options, safety managers can make smarter, more informed choices for their crews. It's all about ensuring every single worker has the right tool for the job's specific demands.

How the Full Brim Design Boosts Outdoor Safety

When you’re working outdoors, the hazards aren’t just coming from straight above. Sun, rain, and flying debris can hit you from every angle, messing with your focus and putting your safety on the line. The 360-degree brim on a full brim hard hat is engineered specifically to tackle these environmental threats. It acts like a personal canopy, giving you way more than just standard impact protection.

This all-around design really shines in three key areas, turning your head protection into a complete defence system against whatever the job site—and mother nature—throws at you.

A Personal Shield Against the Elements

Think of that full brim as your own portable shelter. When a sudden downpour hits a road construction site, the brim is designed to channel all that water away from your face and down your back, not into your collar. This simple function is huge for keeping your vision clear and stopping moisture from soaking into your gear, which helps you stay drier and focused on the task.

Then there's the sun. In bright conditions, that same brim provides serious shade, drastically cutting down the sun exposure on your face, ears, and the back of your neck. These are the spots most vulnerable to sunburn and long-term skin damage. By blocking direct sunlight, the full brim also helps fight off heat stress, a major risk during those long summer shifts. For any crew that consistently works under an open sky, this feature is non-negotiable for their well-being.

The 360-degree brim transforms a hard hat from a passive safety device into an active tool for managing environmental exposure, directly contributing to a worker's comfort, focus, and long-term health.

Deflecting Debris and Splashes

Beyond the weather, that wide brim offers a crucial barrier against hazards that don't fall in a nice, neat straight line. It’s an extra layer of defence that can make all the difference.

Picture these common scenarios:

- Forestry Work: A logger is cutting overhead branches and gets showered with small twigs and sawdust. The full brim deflects all that junk away from their eyes and collar.

- Welding and Grinding: Sparks are flying in every direction. The brim helps stop hot particles from landing on a worker's face or neck.

- Industrial Sites: A minor chemical splash happens nearby. The brim can divert droplets that would otherwise hit sensitive facial skin.

This deflection capability is a key advantage, especially in dynamic environments where small but irritating hazards are a constant problem. To see how this design is put into practice in modern safety gear, you can explore a wide variety of Ridgeline full brim hard hats that make this protective feature a priority. That extra coverage provides a real sense of security, letting workers get their job done with more confidence, knowing they have that extra margin of safety.

Making Sense of Hard Hat Safety Standards

Trying to read the labels inside a hard hat can feel like you’re trying to crack a secret code. But those letters and numbers are your single best guide to staying safe on the job. Don't think of them as technical jargon; see them as a straightforward language of protection. Knowing what they mean is the difference between just wearing a hard hat and wearing the right one.

The standard you'll see most often is ANSI Z89.1, which is the North American gold standard for industrial head protection. This standard sorts hard hats based on two critical things: the type of impact they can handle and how well they protect you from electricity. Getting these two right is how you match your gear to the real-world hazards of your job site.

Understanding Impact Protection: Type I vs. Type II

The first big classification you’ll run into is the "Type." This simply tells you where on the hard hat is designed to take a hit.

- Type I: This is the most common rating you'll find on full brim hard hats. It means the hat is built to protect you from impacts that come straight down on the top of your head. This is perfect for sites where the main danger is something falling from above, like a dropped tool or a piece of debris.

- Type II: This rating offers a higher degree of protection, certified to handle impacts to the top and the sides of your head. You'll see these required in jobs where there's a risk of swinging objects, bumps, or lateral blows.

Most full brim models are Type I because their design is already optimized for overhead hazards and keeping the sun and rain off you. While a Type II hat gives you broader impact coverage, the classic full brim still reigns supreme for its effectiveness against the most common dangers on a construction or industrial site.

Decoding the Electrical Safety Classes

The second part of the code is the "Class," and this is all about electrical insulation. For anyone working near live wires or currents, this detail is completely non-negotiable.

A hard hat's electrical class rating is its promise to protect you from shock. Choosing the wrong class is just as dangerous as wearing no protection at all when electrical hazards are present.

Here’s a simple breakdown of what those ratings mean:

- Class G (General): These hard hats are tested to protect against 2,200 volts. They’re the go-to for general construction and utility work where you might run into low-voltage hazards.

- Class E (Electrical): This is the highest level of electrical protection you can get, with these hard hats tested to withstand a massive 20,000 volts. This class is absolutely essential for electricians and anyone working near high-voltage power lines.

- Class C (Conductive): These hard hats offer zero electrical protection. They are often vented to improve airflow and are only safe for work environments where there is absolutely no risk of electrical contact.

In Canada, provincial bodies like Ontario's MOL and WorkSafeBC enforce these standards, making ANSI-rated head protection a key part of an employer's responsibility. Yet, compliance gaps are still a serious problem. One shocking analysis found that only about 16% of construction workers who suffered a head injury were actually wearing a hard hat. That statistic is a stark reminder of why proper selection and consistent use are so critical.

By learning to read these ratings, you can tell in an instant whether a full brim hard hat is the right tool for your environment. This knowledge is a vital part of a wider safety strategy, which you can explore further in our complete guide to safety supplies.

Full Brim vs. Cap Style: Which Hard Hat Wins?

Choosing between a full brim and a cap-style hard hat isn't just a matter of looks; it's a critical safety decision that hinges on your specific work environment and the hazards you face day in and day out. Each design offers clear-cut advantages, and understanding the trade-offs is key to making sure you've got the best possible protection over your head. The right choice often comes down to a simple balance: broad environmental defence versus task-specific visibility.

The biggest selling point for full brim hard hats is their complete 360-degree coverage. This makes them the undisputed champions for anyone working in wide-open environments where sun, rain, and falling debris are constant threats. That wide brim acts like a personal shield, directing rain away from your collar and significantly cutting down on sun exposure to your face, ears, and neck. That’s a massive benefit for preventing heat stress and sunburn during long shifts outdoors.

Visibility and PPE Compatibility

On the flip side, the cap-style hard hat is the clear winner in situations that demand excellent upward visibility. Its forward-facing bill gives you focused protection from sun glare without blocking your view when you need to look up at overhead equipment, scaffolding, or power lines. That streamlined profile also makes it much easier to wear with other personal protective equipment.

For example, getting a good seal with large, over-the-ear hearing protection is often much simpler with a cap-style hat because there’s no rear brim getting in the way. For workers in high-noise environments who need to wear earmuffs for hours on end, this can be a deciding factor.

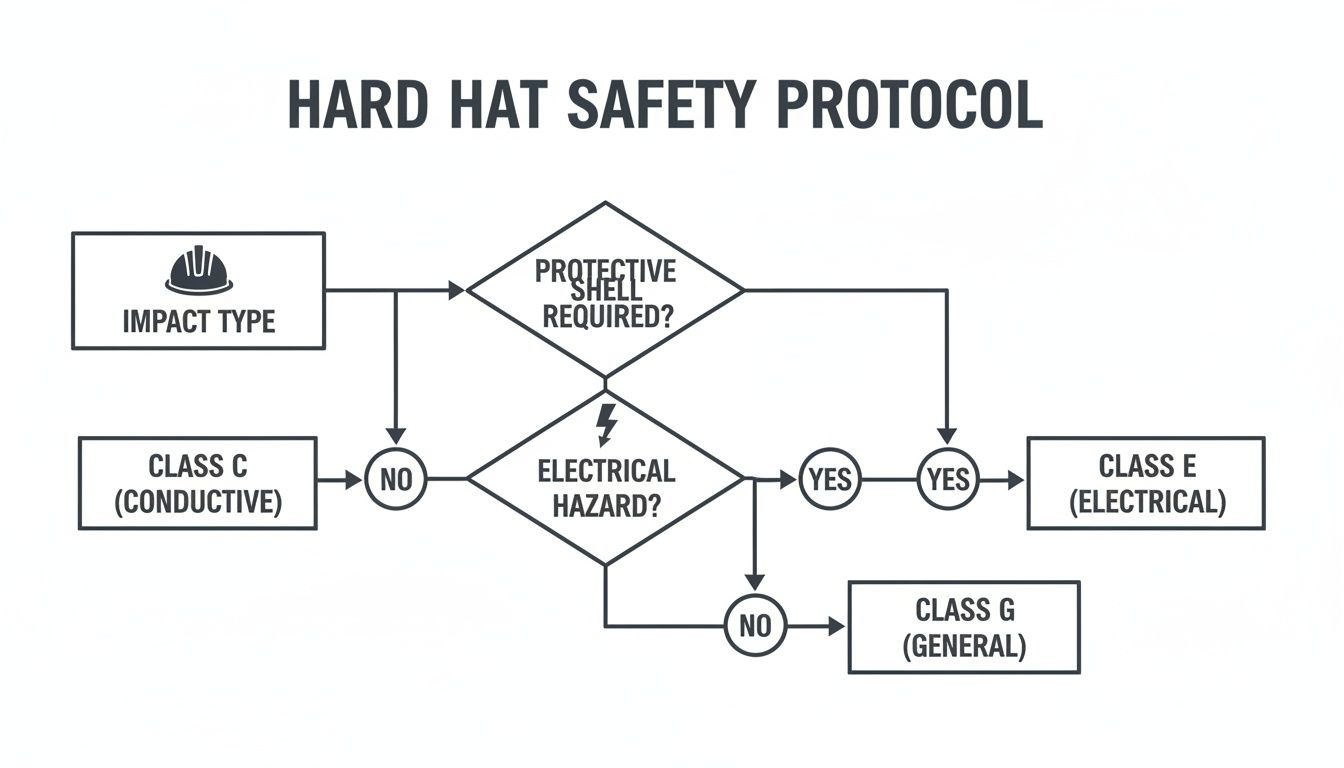

This decision tree infographic is a great tool for visualizing the key factors—impact type and electrical hazards—that should guide your hard hat selection.

The flowchart reinforces that once you’ve nailed down the required impact and electrical ratings for your job, the functional design of the hard hat is the next critical choice to make.

The "winner" in the debate between full brim and cap style is determined entirely by the job. Prioritize 360-degree elemental protection for outdoor exposure and upward visibility for close-quarters or overhead work.

To make the choice even clearer, let's break down how each style stacks up across the most important features.

Full Brim vs Cap-Style Hard Hat Feature Comparison

| Feature | Full Brim Hard Hat | Cap-Style Hard Hat |

|---|---|---|

| Elemental Protection | Excellent: Shields face, neck, and ears from sun and rain. | Good: Front bill blocks glare but leaves neck and ears exposed. |

| Upward Visibility | Limited: The brim can obstruct the view when looking up. | Excellent: Unobstructed view for overhead work. |

| Debris Deflection | Superior: Channels falling debris away from the collar. | Limited: Primarily protects from frontal debris. |

| PPE Compatibility | Good: May interfere with some earmuffs or hoods. | Excellent: Streamlined for easy use with other PPE. |

Ultimately, both styles offer certified safety you can count on; the best one is simply the one that aligns more closely with your daily tasks. If your work demands that clear upward view or seamless integration with other gear, exploring options like these Ridgeline standard hard hats can provide top-tier protection while meeting those specific visibility and compatibility needs.

Matching Your Hard Hat to Your Job's Demands

Picking the right full-brim hard hat isn't a one-size-fits-all deal; it's a critical risk assessment. The best head protection is always the one that’s perfectly matched to the unique hazards of your worksite. A hard hat that’s brilliant on a construction site could be completely wrong for a utility lineman, which is why thinking industry-first is so important.

This means looking beyond just the brim and matching a hat’s materials, ratings, and features directly to the tasks your crew handles every single day. When you get it right, you’re providing protection that isn’t just compliant, but genuinely effective.

Construction and General Labour

For crews on a construction site, the biggest daily battles are usually against top-impact risks and the elements. A standard Type I, Class G full-brim hard hat is the go-to choice here for a good reason. Its 360-degree brim is a lifesaver, providing excellent shade and channelling away rain, which helps keep workers focused and comfortable during long shifts outdoors. High-visibility colours like bright yellow or orange are also a must to ensure workers are easily spotted by heavy equipment operators.

Oil and Gas Industry

The oil and gas sector throws a more complex set of risks into the mix, from chemical exposure to extreme temperatures. Hard hats made from tough materials like high-density polyethylene (HDPE) are vital because they offer superior resistance to chemical splashes and won’t break down. In this field, a Class E rating is often the smarter choice, giving you that extra layer of protection against unexpected electrical hazards in processing facilities.

The right hard hat is an active safety tool, not just a passive piece of equipment. Its features must directly counter the specific, predictable risks of an industry, from electrical currents to chemical exposure.

Electrical and Utility Work

For electricians and utility linemen, there’s simply no room for compromise—electrical insulation is everything. A Class E (Electrical) rating is non-negotiable. These hard hats are tested to protect against a whopping 20,000 volts. The full-brim design is a huge plus here, adding a layer of protection from the weather, which is critical when you’re working on elevated platforms or poles. For any job that involves working up high, understanding your head protection is just one piece of the puzzle; you also need to ensure you have all the necessary working at height safety equipment.

While traditional full-brim hard hats are still a staple, the industry is starting to shift. Recent pilot programs are showing a growing preference for helmet-style (Type II) designs, with one study reporting that over 87% of workers preferred them after trials. This change is driven by their superior ability to handle lateral and rotational impacts from falls—the primary causes of severe traumatic brain injuries. You can learn more about the latest findings in safety helmet studies. This trend is already starting to influence procurement standards on jobsites right across Canada.

Extending the Life of Your Head Protection

A full-brim hard hat is only as good as its condition. Think of its suspension system like the shock absorbers in a truck. The outer shell can look perfectly fine, but if the suspension can't absorb the energy from an impact, the protection is seriously compromised. Regular checks and proper care aren't just good habits; they're non-negotiable for making sure your gear performs when you need it most.

This all starts with a simple daily check. Before you start each shift, take a minute to look for any red flags. Check the shell for cracks, deep gouges, or any discolouration that could signal UV damage. Just as important, give the suspension straps a good look for any signs of fraying, brittleness, or cracking.

Proper Care and Maintenance Routines

A few simple habits can make a huge difference in how long your gear lasts. When it's time to clean your hard hat, stick with mild soap and warm water. Never use harsh chemical solvents or abrasive cleaners, as they can weaken the plastic shell and degrade the suspension system, making it unsafe.

How you store your gear matters just as much. Avoid leaving your hard hat in direct sunlight, like on the dashboard of your vehicle. The extreme heat and constant UV exposure will make the shell brittle over time.

A hard hat has an expiration date for a reason. Both the shell and the suspension system have a limited service life, and respecting the manufacturer's replacement guidelines is a critical part of your personal safety protocol.

Knowing When to Retire Your Hard Hat

While full-brim hard hats are essential for protection against falling objects and the sun, serious head injuries are still a major concern on job sites. Falls are a leading cause of traumatic brain injuries (TBIs) in the construction industry, accounting for about 68% of incidents. This statistic is a stark reminder that while Type I hard hats do their job against top impacts, they may not fully address the rotational or side impacts that are common in falls. To get a clearer picture of these risks, you can discover more insights about workplace TBI statistics.

Always follow the manufacturer's replacement schedule. As a rule of thumb, this usually means replacing the suspension every 12 months and the shell every 2-5 years. However, any hard hat that takes a significant hit must be retired immediately, even if you can't see any damage.

Also, think about how accessories affect performance. For cold weather, only use approved liners, like an FR winter hard hat liner, that are designed to fit properly without getting in the way of the suspension system.

Common Questions About Full Brim Hard Hats

Even with a solid grasp of why full-brim hard hats are a great choice, some practical questions always pop up on the job site. Getting straight answers to these common queries is the key to making sure everyone uses their head protection correctly and safely. Let's tackle some of the most frequent questions we hear from workers and safety managers.

Getting these points sorted helps bridge the gap between just having the right gear and actually using it effectively, every single day.

Can I Wear a Cap or Beanie Under My Hard Hat?

No, you should never wear unauthorized items like a baseball cap, toque, or a standard beanie under your hard hat. Think of it this way: these items create a dangerous gap between the suspension system and your head, which severely cripples the hat's ability to absorb an impact. It's like putting a pillow in front of an airbag—it just won't work the way it was designed.

The only things that are safe to wear underneath are liners that have been specifically designed and approved by the hard hat manufacturer. These are tested to make sure they don't interfere with the suspension system's life-saving function.

How Often Do I Need to Replace My Hard Hat?

This is a big one. You must replace your hard hat immediately after any significant impact, even if you can’t see a scratch on it. The shell's integrity could be compromised in ways that are completely invisible to the naked eye.

Think of a hard hat like a single-use airbag. Once it has done its job by absorbing a major blow, its protective capabilities are spent and it must be retired from service.

Beyond impacts, always follow the manufacturer’s guidelines printed inside the hat. As a general rule of thumb, it's best practice to replace the suspension system every 12 months and the outer shell every 2 to 5 years. This range depends heavily on your work environment and how much it's exposed to things like sunlight, which degrades the plastic over time. Always check the expiration date stamped inside the shell.

What Is the Difference Between Pin Lock and Ratchet Suspensions?

The main difference between these suspension types is all about how you adjust the fit. Both get the job done, but one offers a world of convenience for daily wear.

- Pin-Lock Suspension: This system works just like a classic snapback baseball cap. To get the right fit, you have to take the hard hat off, un-snap the plastic band, and resize it.

- Ratchet Suspension: This is the upgrade. It features an adjustment knob on the back that you can easily turn with one hand. This lets you tighten or loosen the fit on the fly while you’re still wearing the hard hat, guaranteeing a precise and secure fit all day long.

Because it's so easy to use and provides a consistently snug fit, the ratchet suspension is the hands-down favourite for most workers. It lets you make quick adjustments as you move or as conditions change, ensuring your full brim hard hat always stays perfectly in place.

At Refinery Work Wear Canada, we provide a comprehensive range of certified head protection to keep your crew safe. Explore our full selection of safety supplies and find the perfect hard hats for your job's demands.