Finding the most comfortable boots for work isn't about brand loyalty; it's about understanding the science behind all-day support. A truly comfortable work boot is a high-performance system built to cut down on fatigue, absorb shock, and protect your feet, so you end your day feeling strong, not sore.

The Foundation of a Productive Day

Let's be honest, uncomfortable work boots are more than just an annoyance. They're a direct drain on your energy, focus, and productivity. When your feet are screaming, every single task feels harder, your concentration slips, and the risk of an accident goes way up. This guide will take you past the marketing slogans to show you the real engineering behind genuine, long-lasting comfort.

Think of your work boot not as a single piece of footwear, but as a sophisticated suspension system for your body. Just like the suspension on your truck smooths out a bumpy road, a well-designed boot absorbs the relentless impact of walking and standing on unforgiving surfaces. Every single component has to work together in harmony to give you the support you need.

The Boot as a System

To really get what makes a boot comfortable, we need to break it down into its core functional layers. Each part has a specific job, and when they all do their job right, the result is a boot that works with you, not against you.

- The Insole: This is the first point of contact, acting like a custom mattress for your foot. It provides that immediate cushioning and—most importantly—the arch support that forms the bedrock of proper foot alignment.

- The Midsole: This is the unsung hero of comfort. The midsole is your primary shock absorber, dispersing the force of every step you take and stopping that jarring feeling from travelling up your legs and into your back.

- The Outsole: Think of this as the tire tread on your boot. Its job is to give you an unshakeable grip and stability on any surface, from slick concrete to uneven gravel, preventing slips and giving you a confident footing.

By understanding how these pieces fit together, you can look at any boot and evaluate its construction based on real performance, not just how it looks on the shelf. After all, a boot is an investment in your daily well-being and your ability to do your job effectively. A great pair provides the foundation for a safe and productive day, while a bad one can sabotage your shift before it even begins.

For those looking to upgrade their current pair, exploring different work boot accessories can make a huge difference in comfort and support.

Understanding the Anatomy of Boot Comfort

To find a genuinely comfortable work boot, you need to look past the surface and understand how it’s built from the ground up. Think of a quality boot as a three-part system, where each layer has a specific, vital job to do. When these parts work together in harmony, they create a foundation that cushions your feet, absorbs shock, and fights off fatigue all day long.

Let's break down this system and look at the three core layers: the insole, the midsole, and the outsole. Getting a handle on how each one adds to the boot's overall comfort and performance is the secret to making a smart choice that’ll pay you back shift after shift.

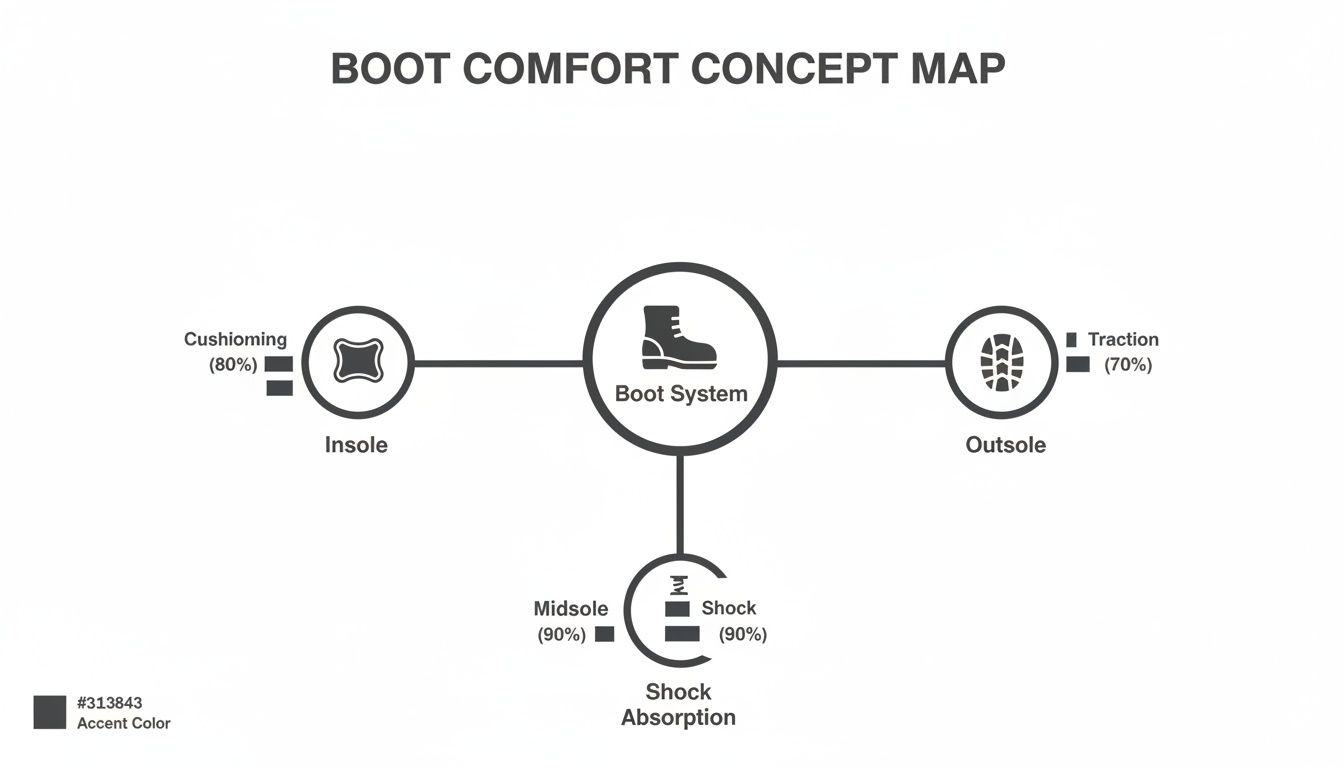

This concept map shows how the three key components of boot comfort—insole, midsole, and outsole—work together as an interconnected system.

Understanding how these three parts function together allows you to assess a boot's engineering for genuine, long-lasting wearability.

Understanding how these three parts function together allows you to assess a boot's engineering for genuine, long-lasting wearability.

The Insole: Your First Line of Defence

The insole, or footbed, is the part your foot is in direct contact with. It's basically the mattress for your boot—its main purpose is to give you immediate cushioning and crucial arch support. A good insole will mould to the unique shape of your foot, spreading pressure out evenly and stopping painful hot spots from forming.

Most of the stock insoles that come with new boots are little more than basic foam placeholders. They might feel okay for a minute, but they usually lack the structured support needed for long hours on your feet. This is why so many seasoned pros upgrade to aftermarket insoles designed for their specific foot type, whether they have flat feet or high arches.

A well-designed insole does more than just cushion your step; it properly aligns your entire foot. This alignment is crucial because it can help prevent common ailments like plantar fasciitis and reduce strain not just on your feet, but also on your knees and lower back.

The Midsole: The Unsung Shock Absorber

Tucked between the insole and the outsole is the midsole, the unsung hero of the boot. This layer is your primary shock absorber, working tirelessly to soak up the force generated every time your heel hits the ground. Without a proper midsole, that impact would shoot straight up your skeletal system, leading to joint pain and fatigue.

Midsoles are typically made from one of two materials:

- EVA (Ethylene Vinyl Acetate): This is a lightweight, flexible foam that gives you excellent cushioning, much like what you'd find in a running shoe. The downside is that it can compress and lose its supportive punch over time with heavy use.

- PU (Polyurethane): A much denser and more durable foam that offers fantastic longevity and resists getting packed down. PU midsoles provide firm, reliable support that holds up to the daily grind of a tough job site, making them the go-to choice for heavy-duty comfortable boots for work.

The Outsole: Where Grip Meets Stability

Finally, we get to the outsole—the rugged layer that actually hits the ground. Think of it as the tire tread on your boot. Its job is to provide traction, stability, and protection from things like punctures and job-site hazards. The design of the tread, or lug pattern, is what determines how well the boot will grip on different surfaces.

Deeper, more aggressive lugs are what you want for loose ground like mud or gravel, while flatter, slip-resistant patterns are better for smooth, wet surfaces like concrete or steel decking. The outsole material itself, usually a specialized rubber compound, is engineered to resist oil, chemicals, and abrasion, ensuring it stays effective for the long haul.

The importance of a high-quality, slip-resistant outsole can't be overstated. A slip-resistant footwear program at a University of California campus, for example, led to a 75% reduction in slips and falls in just its first year. This really shows how investing in boots with superior outsoles doesn’t just boost comfort—it's a critical step in reducing lost-time injuries.

You can explore more data on the impact of footwear programs by reading these findings on contractor trade injuries. By understanding these three core components, you’re now equipped to evaluate any work boot based on its construction and material science, not just its looks.

How Safety Features Affect All-Day Wearability

Modern safety features are your first line of defence against job site hazards, but they shouldn't feel like a punishment for your feet. The old belief that protection had to come at the expense of comfort is completely outdated. Thanks to huge leaps in material science, you can get essential, CSA-approved protection without sacrificing the lightweight flexibility you need for all-day wear.

The key is understanding how different safety components impact a boot's weight, fit, and overall feel. By choosing the right technology for your specific work environment, you can find a pair of comfortable boots for work that meets every safety standard without dragging you down.

The Great Toe Debate: Steel vs. Composite

The safety toe is probably the most famous protective feature, but not all of them are created equal. The material used in that toe cap has a massive effect on the boot's comfort and your energy levels at the end of the day.

To make it easier, let's break down the big three you'll encounter on the job site.

Safety Toe Material Comparison

| Material | Weight | Thermal Conductivity | Protection Level | Typical Fit Profile |

|---|---|---|---|---|

| Steel | Heaviest | High (Conducts heat/cold) | Maximum impact & compression resistance | Can be bulky, sometimes narrower |

| Composite | Lightest | Low (Doesn't conduct) | Meets CSA impact & compression standards | Often allows for a roomier, more anatomical toe box |

| Aluminum | Lighter than steel | High (Conducts heat/cold) | Meets CSA impact & compression standards | Can offer a thinner, less bulky profile than steel |

As you can see, the choice isn't just about protection—they all have to meet the same strict CSA standards. It's really about the feel on your foot.

Steel toes are the classic, traditional choice, known for their brute strength. But that strength comes with a price: weight. Steel also conducts temperature, making your feet feel colder in the winter and hotter in the summer.

Composite toes, made from non-metallic materials like carbon fibre or Kevlar, are the modern answer. They're significantly lighter than steel, which cuts down on foot fatigue over a long shift. Because they don't conduct electricity or temperature, they're the go-to for electricians and anyone working in extreme weather. You can see how brands are using this tech in our guide to Timberland PRO work boots.

The weight difference might not seem like a big deal when you pick up the boot, but it adds up with every step. A boot that's just 200 grams lighter can save you from lifting an extra tonne of weight over the course of an average workday. That reduction in strain is a game-changer for how you feel at clock-out.

Puncture Plates: Underfoot Flexibility

Just as critical as what’s protecting your toes is what lies beneath your foot. Puncture-resistant plates shield you from sharp objects like nails and screws, but their construction directly impacts how the boot flexes as you walk.

-

Steel Plates: Like their toe-cap cousins, steel plates offer maximum puncture resistance. The trade-off is their rigidity, which can make the boot feel stiff and fight against the natural rolling motion of your foot.

-

Fabric Plates: Modern boots often use flexible, non-metallic plates woven from high-tech aramid fibres. These plates meet CSA safety standards while allowing the boot's sole to bend and move naturally, much like a regular shoe. This flexibility is a lifesaver for trades that require a lot of crouching, kneeling, or climbing.

Choosing flexible fabric plates can dramatically improve comfort for active jobs without ever compromising on safety.

Understanding the Broader Safety Picture

It's important to remember that the features in your boots are part of a much larger system of workplace safety. Your boots are your last line of defence, but a safe work environment is engineered from the ground up.

For example, understanding things like OSHA-compliant warehouse safety designs helps put it all in perspective. A well-designed site minimizes hazards in the first place, making your PPE's job that much easier.

Ultimately, picking the right safety features is a balancing act. You have to meet the non-negotiable standards for your job while actively seeking out the modern, lightweight materials that make those standards comfortable to live with day in and day out. By choosing boots with composite toes and flexible puncture plates, you get certified protection that works with your body's natural mechanics, not against them.

Choosing the Right Materials for Your Job Site

The most comfortable work boots are the ones built for your world. A boot that feels like a dream on a dry factory floor can turn into an absolute nightmare in the rain or cold. Getting a handle on how different materials perform isn't just about durability; it's about picking footwear that gives you targeted comfort, so you can focus on the job instead of your aching feet.

Think of it as creating a personal microclimate for your feet that’s perfectly tuned to your worksite. Whether you're up against freezing temperatures, relentless dampness, or scorching heat, the right materials will keep your feet dry, supported, and comfortable all shift long.

Mastering Cold Weather Conditions

Working in the cold calls for insulated boots, but piling on the grams isn't always the answer. The real trick is to match the insulation level to how active you are. Insulation works by trapping your body heat, just like the fill in a good winter jacket.

-

200g Insulation: This is your go-to for cool conditions or high-energy jobs where you’re moving around a lot and making your own heat. It provides just enough warmth to take the edge off without making your feet sweat.

-

400g-600g Insulation: For most cold-weather gigs, this is the sweet spot. It offers serious warmth for workers who have a mix of active periods and standing still, making it a solid, versatile choice for many Canadian job sites.

-

800g+ Insulation: This level is reserved for extremely cold, low-activity work. If you're spending hours sitting still in freezing temps, like operating machinery or monitoring a site, this heavy-duty insulation is what you need to stop heat from escaping.

Getting this wrong can seriously backfire. Too much insulation when you're working hard leads to sweaty feet. Sweaty feet get cold and damp, which is a fast track to blisters and misery.

Conquering Wet and Damp Environments

Nothing tanks a workday faster than wet feet. It’s not just the discomfort—soggy skin gets soft, making it incredibly prone to painful blisters and fungal infections. The fix is a boot with a waterproof and breathable membrane.

A waterproof membrane is like a high-tech bouncer for your boot. It’s full of microscopic pores that are tiny enough to block big water molecules from getting in, but just big enough to let smaller water vapour molecules (your sweat) get out. This one-way gate is the secret to keeping you dry from the outside elements and your own sweat.

Materials like GORE-TEX are legendary for this kind of technology. They build a complete waterproof bootie inside the boot's structure, which means even if the outer leather gets soaked, your feet stay bone dry. That breathability is non-negotiable for all-day comfort in the wet.

Staying Cool in Hot Conditions

For anyone working in hot climates or even fast-paced indoor jobs, breathability and moisture control are everything. A heavy, insulated boot will feel like a swamp in no time, leading straight to overheating and discomfort.

You want to look for boots made with lightweight, breathable materials. Unlined leather boots or those with nylon mesh panels offer much better airflow, helping heat escape and keeping your feet feeling cooler. The inside lining is just as critical. A quality moisture-wicking liner will actively pull sweat away from your skin, pushing it to the boot's outer layers where it can evaporate. When you're thinking about the specific qualities of different materials, like breathability and toughness, a broader knowledge of textiles is helpful; for example, this guide on understanding different fabric properties can be quite useful. This is what keeps your feet feeling dry and fresh, even when the heat is on.

By matching your boot’s materials to your work environment—whether that means insulation for the cold, waterproofing for the wet, or breathability for the heat—you turn your footwear into an asset, not a distraction.

A Practical Guide to Finding the Perfect Fit

All the high-tech materials and safety features in the world won't do you any good if your boots don't fit. A poor fit is the fastest way to turn a top-dollar investment into a source of daily misery, leading to blisters, hot spots, and even long-term foot problems. Getting the fit right is the single most important step in finding truly comfortable boots for work.

This is your practical, no-nonsense checklist to nail the fit every single time. It's a simple process that goes way beyond your standard shoe size to account for the actual shape of your feet and the real demands of your job. By dodging a few common mistakes, you can make sure your boots deliver the lasting comfort and support you paid for.

The In-Store Fit Checklist

Never, ever buy work boots without trying them on first. And when you do, follow these steps to mimic a real workday as closely as possible. This is the only way to get an accurate feel for how they'll perform when it actually counts.

-

Shop in the Afternoon: Your feet naturally swell as the day goes on. Trying on boots late in the day or right after a shift means you’re fitting them at their largest, which prevents that dreaded feeling of your boots getting tighter by lunchtime.

-

Bring Your Work Socks: Don't just use those thin little dress socks they have at the store. The thickness of your usual work socks makes a huge difference in the fit, so always test boots wearing the exact pair you'd have on-site.

-

Check Length and Width: Once the boot is laced up, you should have about a thumb's width (~1 cm) of room between your longest toe and the very end of the boot. Your toes need to be able to wiggle and spread out freely without feeling squeezed.

Key Fit Issues to Watch For

With the boots on your feet, run through a few quick tests to spot common problems that turn into major pain down the road. Pay close attention to how your foot is moving—or not moving—inside the boot.

A perfect fit feels snug and locked-in around your heel and midfoot, but gives you plenty of room up in the toe box. Any serious pinching, rubbing, or sloppy movement is a red flag that will only get worse over a long shift.

-

Heel Slippage: Take a walk around the store and focus on your heel. A tiny bit of lift (around a quarter-inch) is perfectly normal, but if your heel is sliding up and down like crazy, the boot is either too big or the heel cup just isn't the right shape for your foot. That spells friction and painful blisters.

-

Toe Box Constriction: Get up on the balls of your feet and simulate crouching down like you would on the job. If you feel any pinching or cramping across the front of your foot, the toe box is too narrow. This is a critical check, especially with steel or composite-toe boots.

To see how modern boot designs are built to provide a more natural, comfortable fit right out of the box, you might want to look into the features found in some of today's top-rated KEEN work boots.

Breaking in Your New Boots Properly

Even a boot that fits like a glove needs a break-in period to truly mould to your feet. This process shouldn't be painful. The whole point is to gradually soften up the leather and let the footbed conform to your specific arch and pressure points.

Start by wearing your new boots around the house for a couple of hours a day for about a week. This lets all the materials flex and stretch in a low-stress environment. Once they feel good indoors, start wearing them on the job site for the first half of your shift, then switch back to your old pair. After a few days of this, they should be ready for full-time duty. This patient approach prevents the agony that comes from trying to force stiff, new boots through a 12-hour workday.

Managing a Company-Wide Footwear Program

Outfitting an entire crew with the right footwear is about so much more than just checking a box on a safety form. It’s a serious investment in your company’s most valuable asset: your people. A well-managed corporate footwear program is a powerful tool for boosting safety, improving morale, and cutting down the massive costs that come with workplace injuries.

Treating high-quality, comfortable boots for work as just another operational expense is a mistake. A better way to look at it is as a critical part of your risk management strategy. A comfortable worker is a more focused and productive worker. And feet that are properly supported day in and day out lead to fewer strains, slips, trips, and falls over the long haul. This proactive thinking has a direct impact on your bottom line by reducing lost-time incidents and workers' compensation claims.

Building a Smart and Scalable Program

Putting a successful program in place involves more than just picking a boot out of a catalogue. The best strategies are built on a solid foundation of partnership, clear policies, and streamlined logistics that make life easier for everyone, from management to the crew on the ground.

A few key elements make all the difference:

- Negotiating Bulk Discounts: When you partner with a dedicated supplier, you can leverage your purchasing power. This often unlocks major savings and gives you access to a much wider selection of specialized boots.

- Managing Employee Allowances: Setting up a clear allowance or voucher system empowers your team. It lets them choose the boots that actually fit their feet and their specific job, which is a huge win for comfort and proper sizing.

- Streamlining Procurement: A managed program takes the headache out of ordering, distribution, and returns. It cuts through the administrative red tape and makes sure your crew gets the right gear without any frustrating delays.

If you’re looking to simplify this entire process, you might want to look into a managed FR uniform and work boot program. These services can handle everything from fitting to final delivery.

The Regulatory and Financial Imperative

Beyond all the practical benefits, there are some pretty compelling regulatory and financial reasons to set up a formal footwear program. In some jurisdictions, the legal landscape makes employer payment for required protective footwear a major issue. In California, for example, Cal/OSHA standards and state labour laws generally require employers to provide or reimburse employees for safety boots.

A recent spike in litigation has highlighted the huge financial risks for companies that don't comply. By establishing a clear policy and budget for footwear—much like the state does for its own workers—you protect your company from both regulatory fines and civil lawsuits.

Ultimately, a company-wide footwear program isn't just about safety compliance; it’s a clear message to your employees that you genuinely value their well-being. This kind of investment builds a stronger safety culture, reduces your risk, and creates a more resilient, productive workforce from the ground up.

Common Questions About Work Boot Comfort

Even with all the technical details sorted, a few practical questions always pop up when you're trying to find the right pair of boots. Let's tackle some of the most common concerns head-on, so you can feel totally confident in your choice.

How Long Should a Pair of Work Boots Last?

In a demanding, high-wear environment like a construction site, a quality pair of work boots will typically give you 6 to 12 months of solid service. If you're in lighter conditions, you might even stretch that to 18 months.

The boots themselves will tell you when it's time for a new pair. Look for tell-tale signs like worn-out treads that have lost their grip, deep cracks in the leather or synthetic uppers, and a noticeable drop in cushioning and support. The biggest giveaway? If your feet are aching at the end of every shift, it's a sure sign the boot's internal support system has given up.

A boot's lifespan is directly tied to its upkeep. For detailed advice, check out our guide on how to properly clean and maintain work boots to get the most out of your investment.

Can I Make My Current Boots More Comfortable?

Yes, you often can—within reason. The single most effective upgrade is swapping out the flimsy stock insole for a quality aftermarket one designed for your foot type. This one change can dramatically improve cushioning and arch support. Pairing that with proper moisture-wicking work socks is another game-changer for preventing blisters and managing sweat.

Just remember, these are fixes, not miracles. If your boots are fundamentally the wrong size—too narrow, too short, or the wrong shape for your foot—no insole or sock in the world is going to correct that.

Are Lighter Boots Less Durable?

Not anymore. It's an old myth that heavy boots were the only durable boots, but modern materials have completely changed the game.

Today's advanced components like composite safety toes, flexible fabric puncture plates, and lightweight PU midsoles offer incredible protection and longevity without weighing you down. We've moved past the days when durability meant strapping slabs of steel and thick leather to your feet.

When you're judging how tough a boot is, focus on the quality of its construction and the materials used, not just the number on the scale. Modern engineering means you really can get the best of both worlds: toughness and comfort.

At Refinery Work Wear Canada, we provide CSA-approved safety footwear designed for the toughest jobs, ensuring your crew is protected and comfortable. https://canada.refineryworkwear.com