When you’re talking about essential PPE, high-visibility rain jackets are right at the top of the list. They’re built to keep workers both seen and safe, especially when the weather turns nasty and the light starts to fade. By combining waterproof materials with bright, fluorescent backgrounds and retroreflective tape, these jackets do double duty: they keep you dry while making sure you don't disappear into the background.

Why High-Visibility Rain Jackets Are Non-Negotiable Work Gear

Picture a road crew patching asphalt in the pouring rain at dusk, or an energy sector tech inspecting a line on a foggy morning. In those situations, being visible isn't just a nice feature—it's a lifeline. This is why hi-vis rain jackets are considered non-negotiable PPE across Canada's most demanding worksites. They’re much more than just rain gear; they're a critical safety tool.

These jackets are your first line of defence against the twin threats of low visibility and harsh weather. Without them, a worker can easily become invisible to drivers and heavy equipment operators, which dramatically increases the risk of a serious or even fatal accident. As highlighted in guides for high-risk operations, like this Emergency Gas Line Repair Safety Guide, worker visibility can literally be the difference between life and death.

The Role of Hi-Vis in Canadian Industries

Here in Canada, where the weather can shift from clear to severe with very little warning, the need for this gear is critical across several key industries. The market data tells the same story.

In Canada's high-visibility apparel market, jackets are the largest segment, reflecting their critical role in keeping workers safe. Valued at USD 166.42 million in its base year, the market is projected to surge to USD 295.57 million by 2033, driven by strict CSA Z96 standards.

That kind of growth shows just how seriously employers are taking visibility. From sprawling construction sites to remote utility maintenance, making sure every single team member has a compliant high-visibility rain jacket is a cornerstone of building a real safety culture. You can find a full collection of jackets and other essential gear that meet these standards in our high visibility workwear section.

This guide is here to walk you through the key details, helping you make informed choices that not only ensure compliance but, more importantly, protect your crew from preventable accidents. We’ll get into the specific safety standards, the technology behind the materials, and the industry-specific needs that define truly effective gear.

Decoding Canadian Safety and FR Standards

Trying to make sense of the web of safety standards can feel like reading a technical manual in the dark. But getting a handle on these codes is absolutely essential for making sure your high-visibility rain jackets provide real, life-saving protection. In Canada, the big one for visibility is CSA Z96, while flame resistance usually points to standards like NFPA 2112 and NFPA 70E.

Think of these standards not as bureaucratic red tape, but as a blueprint for safety. They take the complex physics of light, fire, and electricity and translate them into practical, real-world requirements for your gear. A jacket that meets these standards isn't just another piece of clothing; it's a meticulously engineered tool designed to keep you safe when things go wrong.

Understanding CSA Z96 High-Visibility Classes

The cornerstone of Canadian visibility standards is CSA Z96. This regulation sorts high-visibility safety apparel (HVSA) into three distinct classes. The class is determined by the total area of fluorescent background material and retroreflective tape on the garment. The class you need is tied directly to your work environment and the level of risk you face every day.

To help clear things up, here’s a quick breakdown of what each class means for workers on the ground.

CSA Z96 High-Visibility Classes Explained

| CSA Z96 Class | Required Retroreflective Material | Required Background Material | Typical Work Environment & Risk Level |

|---|---|---|---|

| Class 1 | Minimum level required. | Minimum level required. | Low-risk environments, away from traffic. Think parking lot attendants or warehouse staff. |

| Class 2 | More reflective tape than Class 1, often in a harness pattern. | More fluorescent material than Class 1. | Medium-risk areas near traffic moving under 80 km/h or where sightlines are poor. Think municipal workers or survey crews. |

| Class 3 | Highest level, with reflective bands around arms and legs for full-body outline. | Highest level of fluorescent material coverage. | High-risk environments near traffic exceeding 80 km/h. Mandatory for highway construction crews and emergency responders. |

As you can see, the higher the risk, the more visibility coverage the standard demands to keep workers seen and safe.

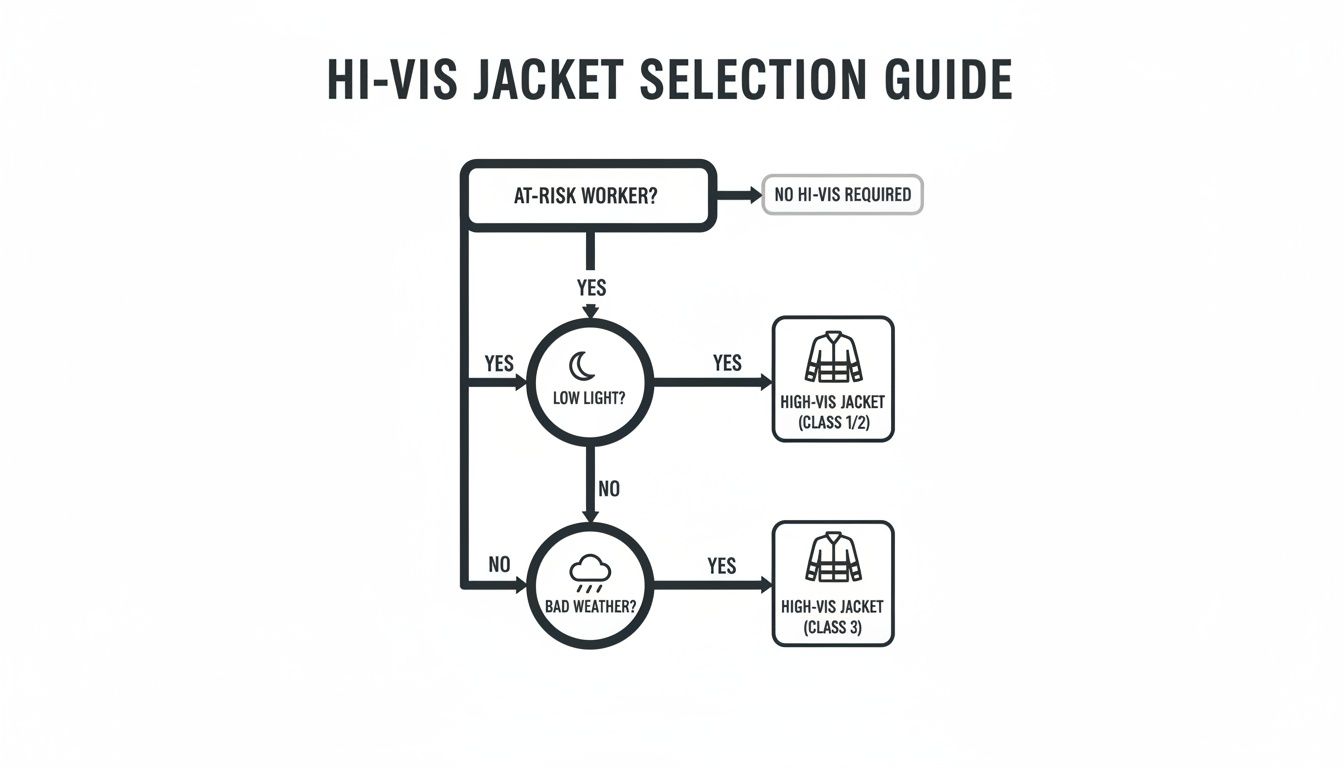

The infographic below offers a simple decision tree to help you figure out which high-visibility rain jackets are right for your team's specific risk level.

This visual guide breaks it down perfectly. The selection process always starts with identifying at-risk workers, then you factor in environmental conditions like low light and foul weather to dial in the right gear.

Layering on Flame-Resistant (FR) and Arc-Rated (AR) Protection

For a lot of Canadian workers, especially in sectors like oil and gas or electrical utilities, just being seen is only half the battle. Your gear also has to shield you from thermal hazards like flash fires and arc flashes. This is where Flame-Resistant (FR) and Arc-Rated (AR) standards come into play.

A common and dangerous mistake is assuming any hi-vis rain jacket will do the job in these environments. A standard polyester jacket can melt onto a worker's skin in seconds during a thermal event, causing horrific, life-altering injuries. That’s why specialized FR rainwear isn't just a good idea—it's non-negotiable.

A core principle of thermal hazard protection is this: your outermost layer is your primary line of defence. If your rain jacket isn't FR-rated, it can completely compromise the entire FR clothing system you're wearing underneath, rendering it useless when you need it most.

Two of the most critical standards you need to look for are:

- NFPA 2112: This standard lays out the minimum performance requirements for FR garments to protect workers from industrial flash fires. A jacket certified to NFPA 2112 has been tested to ensure it won’t melt, drip, or keep burning after the fire is out, which dramatically reduces the severity of burn injuries. To learn more, check out our in-depth guide on what the NFPA 2112 standard means for your workwear.

- NFPA 70E: This standard is all about electrical safety in the workplace, specifically protection against arc flash. Garments that comply with NFPA 70E are given an Arc Rating (measured in cal/cm²), which tells you exactly how much thermal energy the fabric can block before a second-degree burn is likely.

Choosing the right jacket means carefully matching its FR and AR ratings to the specific, identified hazards of your job site. Understanding how different materials perform under extreme conditions is key to building a robust safety program. For a wider perspective, it's useful to explore how various industries approach fire safety regulations and compliance. This knowledge helps ensure you're creating a comprehensive safety system that leaves absolutely nothing to chance.

Anatomy of a High-Performance Rain Jacket

So, what really separates a decent hi-vis rain jacket from a truly high-performance one? It all comes down to the details. A premium jacket isn't just a single piece of fabric; it’s a specialized system where every single component is engineered for a specific, life-saving purpose.

From the waterproof membrane that keeps you dry to the precise placement of reflective tape that keeps you seen, these features work together to keep workers safe and comfortable in the toughest conditions. Let’s pop the hood and see what makes these garments tick.

Unpacking Waterproofing and Breathability

At its core, a rain jacket’s number one job is to keep water out. But the way modern jackets do this is far more advanced than a simple plastic poncho. High-performance jackets use technical fabrics with specific waterproof ratings, typically measured in millimetres (mm).

A rating of 10,000mm, for example, means a one-inch square of the fabric can hold up a column of water 10,000mm tall before a single drop leaks through. For a worker caught in a relentless downpour, that’s the difference between staying dry for an entire shift and being soaked to the bone in minutes.

But keeping the rain out is only half the battle. If a jacket is completely sealed, it’s also going to trap all your body heat and sweat, leaving you just as wet from the inside. This is where breathability comes into play.

Think of a breathable membrane as a smart gatekeeper. It has microscopic pores small enough to block large water droplets from rain but large enough to let tiny water vapour molecules from your sweat escape.

This clever technology allows the jacket to "breathe," getting rid of that clammy, uncomfortable feeling you get during physical work. A high breathability rating means that even when you're working hard, your gear is working with you to regulate your temperature and keep you dry from the inside out. This dual-function design is the hallmark of a professional-grade hi-vis rain jacket.

The Science of Being Seen: Retroreflective Tape

The bright, fluorescent background of a hi-vis jacket is great for daytime visibility, but it’s the retroreflective tape that makes a worker stand out in the dark. This isn't just some shiny silver fabric; it's a piece of precision-engineered safety tech. The tape is designed to catch light from a source, like a truck's headlights, and bounce it directly back to that source.

There are two main types of retroreflective technology you’ll find on modern jackets:

- Glass Bead Tape: This common type uses microscopic glass beads embedded in the material. When light hits the beads, it bounces around inside them before being reflected back. It's an effective and reliable technology.

- Prismatic Tape: This is a more advanced option that uses tiny, sharp-angled micro-prisms. It reflects light far more efficiently than glass beads, often appearing significantly brighter from greater distances and wider angles.

The placement of this tape is just as crucial as its quality. Canadian standards require specific patterns to make sure workers are recognizable as human figures from every direction. This is why you always see horizontal bands around the torso and arms.

One of the most critical design elements required by CSA Z96 is the unmistakable 'X' pattern on the back of the jacket. This simple but brilliant feature instantly tells an equipment operator or driver which way a worker is facing, helping them predict movement and avoid a collision. To dive deeper into how these patterns are designed for maximum safety, you can learn more about our custom reflective striping options.

Essential Features for On-the-Job Functionality

Beyond the core safety technologies, a high-performance jacket is packed with smart features designed for comfort, durability, and practicality on the job site. When you're choosing gear, keep an eye out for these critical components that signal a well-designed garment.

A major weak point in any rain jacket is its seams. Even the best waterproof fabric will fail if water can seep through the tiny holes left by stitching. That's why premium jackets feature sealed or welded seams, where a waterproof tape is applied over the stitching on the inside to create a completely impenetrable barrier.

On top of that, small design choices can have a huge impact on a worker's day. Look for these practical additions:

- Storm Flaps: These are fabric flaps that cover zippers to stop wind and rain from getting through the teeth.

- Adjustable Cuffs and Hems: Being able to create a snug fit at the wrists and waist prevents water from running up your arms or wind from blowing up your back.

- Detachable or Stowable Hood: A good hood should be large enough to easily fit over a hard hat and adjustable so you can maintain a clear line of sight.

By understanding these key components—from waterproof ratings and breathability to retroreflective tech and seam sealing—you can build a mental checklist to make sure the gear you choose will deliver real safety and comfort, day in and day out.

How to Choose the Right Jacket for Your Industry

Picking the right high-visibility rain jacket isn't a one-size-fits-all deal. The gear that keeps a hydro lineman safe in rural Alberta is a world away from what a construction worker needs on a rainy Vancouver job site. A truly effective jacket is chosen not just for the weather but for the very specific hazards you face every single day.

Getting this right is the most critical step. It means looking past the bright colours and digging into specialized protections like flame resistance, arc flash ratings, and pure, rugged durability. It’s about choosing a tool that’s actually built for the task at hand.

Oil and Gas Operations

For anyone on an oil and gas site, the risk of a flash fire is a constant, serious threat. In this kind of environment, a standard polyester rain jacket isn't just a poor choice—it's a dangerous liability. When hit with intense heat, non-FR materials can melt and literally fuse to your skin, causing devastating injuries.

This is exactly why flame-resistant (FR) high-visibility rain jackets are an absolute, non-negotiable requirement. These garments are engineered to self-extinguish the moment the source of ignition is gone, buying you precious seconds to escape and drastically reducing the severity of potential burns. You can explore a full range of certified FR outerwear by reading our guide on flame-resistant jackets.

Utilities and Electrical Work

Electrical workers face a totally different kind of thermal hazard: an arc flash. This is a violent, explosive blast of energy that can generate temperatures hotter than the sun's surface. For these professionals, an Arc-Rated (AR) jacket isn't just a good idea; it's essential.

These jackets are tested and given an Arc Thermal Performance Value (ATPV), which is measured in calories per square centimetre (cal/cm²). This number tells you how much thermal energy the fabric can block before you would likely suffer a second-degree burn.

Choosing the right AR jacket means matching its ATPV rating to the potential incident energy calculated for your specific work environment. A higher ATPV rating offers greater protection against more powerful arc flash events.

Construction and Road Crews

On construction sites and along Canada's roadways, workers are surrounded by heavy machinery, high-speed traffic, and abrasive materials day in and day out. Here, the priorities shift to maximum visibility and sheer, rugged durability. A CSA Z96 Class 3 high-visibility rain jacket is paramount for anyone working near traffic moving over 80 km/h.

These jackets give you full-body visibility with reflective tape on the arms and legs, making sure drivers can recognize you as a human figure from a distance. Durability is also a huge factor. Look for jackets made from heavy-duty materials like 300-denier polyester with reinforced stitching that can stand up to the daily grind of construction work.

Matching Gear to Canadian Climates

Your jacket's performance is also dictated by where in Canada you're working. A person on the perpetually damp BC coast needs something very different from a technician facing a brutal prairie winter.

-

Wet Coastal Regions (BC): The main challenge here is constant rain and milder temperatures. Lightweight, highly breathable jackets with excellent waterproof ratings (10,000mm or higher) are perfect. The goal is to stay dry from the outside without getting soaked in sweat on the inside.

-

Prairie Winters (AB, SK, MB): Out here, extreme cold demands a completely different strategy. Insulated, multi-layer systems are crucial. This usually means an FR base layer, a warm mid-layer, and a heavy-duty, insulated FR outer shell that’s both waterproof and windproof.

-

Eastern Canada (ON, QC, Maritimes): This region gets a mix of everything—heavy snow, freezing rain, and humid summers. Versatility is the name of the game. A 3-in-1 jacket system, with a waterproof outer shell and a zip-in fleece or insulated liner, lets you adapt your gear to whatever the day throws at you.

As weather becomes more unpredictable, the demand for this kind of specialized gear is only growing. Canada's rainwear market, which is critical for sectors using high-visibility rain jackets, is projected to expand by over USD 20 million between 2025 and 2030, driven by the need for functional gear on energy and construction sites. You can discover more insights about the growing demand for industrial rainwear from recent market analyses.

Extending the Life and Safety of Your Gear

A top-tier hi-vis rain jacket isn't just another piece of clothing; it's a serious investment in your personal safety. To get the most out of that investment and make sure your gear is ready to perform when you need it most, proper care and routine inspection are non-negotiable.

Think of it like any other specialized tool on the job site. You wouldn't neglect your power tools, and your PPE deserves the same respect. Tossing these advanced jackets in the wash with regular household detergents is a common but costly mistake. Many laundry soaps contain fabric softeners, bleach, or other harsh additives that can literally strip away the flame-resistant (FR) treatments and waterproof coatings, compromising the very features built to protect you.

The golden rule is simple: always follow the manufacturer's care label. Most of the time, this means washing with a mild detergent in cold water and steering clear of bleach or fabric softeners completely. This simple habit preserves the technical fabrics and ensures your jacket remains a reliable piece of life-saving equipment.

Your Pre-Shift Inspection Checklist

Before you even think about heading out for a shift, a quick visual once-over can catch a small problem before it becomes a major hazard on the job. It only takes a minute, and it’s one of the most powerful safety habits you can build. Make it part of your daily routine.

Taking 60 seconds to inspect your jacket isn't just about ticking a box for compliance; it's about confirming your gear is ready to protect you today. A small tear or some faded tape can dramatically reduce its effectiveness in an emergency.

Here’s a straightforward checklist to run through every day:

- Check for Physical Damage: Look closely for any rips, tears, burns, or punctures. A compromised outer shell is an open door for moisture or, in an FR garment, a failure point during a thermal event.

- Inspect Reflective Tape: Make sure the retroreflective tape isn't cracked, peeling, or looking dull and faded. Damaged tape drastically cuts down your visibility in low-light conditions.

- Test Zippers and Closures: Run every zipper up and down to ensure they move smoothly. Check that storm flaps and cuffs are secure enough to create a proper seal against the elements.

- Look for Contamination: Scan for any stains from oil, grease, or other flammable substances that didn't come out in the wash. These contaminants can act as fuel and compromise the FR properties of your jacket.

This mindset of regular care and inspection applies to all your critical PPE. For those who rely on a complete FR system, maintaining your bib overalls is just as important. You can find detailed care instructions for that essential gear in our guide to maintaining your FR bib overalls.

Common Questions We Hear About Hi-Vis Rain Jackets

Even with all the specs and standards laid out, you’re bound to have a few practical questions when it comes to choosing and using your gear. That's perfectly normal. Getting the right answers is key to making sure you and your crew are properly protected on the job.

Let's dig into some of the most common things workers and safety managers ask us.

How Often Should I Replace My Hi-Vis Rain Jacket?

There’s no hard-and-fast expiry date stamped on a hi-vis rain jacket. Its lifespan is all about wear and tear, and knowing when to retire it is a non-negotiable part of staying safe. If a jacket has obvious physical damage like rips, burns, or punctures that compromise its waterproof or FR layers, it needs to be taken out of service immediately.

But the most critical factor is visibility. Once the fluorescent background colour gets badly faded or the reflective tape is cracked, peeling, or has lost its shine, it no longer meets CSA Z96 standards. It’s done. For FR gear, if it gets contaminated with something flammable that you can’t wash out, it’s also a major hazard and must be retired.

A regular, documented inspection schedule is the only way to be sure every jacket out on the site is still compliant and effective. This isn't guesswork; it's about building a reliable safety culture.

Can I Wear a Regular Hoodie Under My FR Rain Jacket?

Absolutely not. Layering a standard cotton or polyester hoodie under your FR rain jacket is one of the most dangerous—and common—mistakes you can make. It completely cancels out the protection your specialized jacket was designed to provide.

Think about it: during a flash fire or arc flash, that cotton hoodie will ignite and keep on burning long after the initial event is over. A polyester one is even worse; it will melt directly onto your skin. This can cause horrific, life-altering burns, even if your outer FR jacket self-extinguishes exactly like it’s supposed to.

You have to think in terms of a complete system. To be fully protected, every single layer you wear, from your base layer to your outerwear, has to be FR-rated.

What Is the Difference Between Waterproof and Water-Resistant?

People throw these terms around like they mean the same thing, but for a worker caught in a downpour, the difference is everything. Getting this right is critical when choosing your high visibility rain jackets.

-

Water-Resistant: This is gear that can fend off a light drizzle or a bit of mist for a short time before it starts to soak through. It offers very little real protection in sustained wet weather.

-

Waterproof: This is the real deal. Waterproof gear is engineered to be a complete barrier against water, keeping you dry even during a relentless, shift-long downpour in the harshest conditions.

For any kind of industrial work, you should only be looking for jackets that are fully waterproof. Check the technical specs for a high water column rating (something like 10,000mm is a good benchmark) and look for critical features like sealed or welded seams. Those seams are what stop water from sneaking in through the tiny holes left by the stitching, ensuring you stay dry, safe, and focused on the job, no matter what the sky throws at you.

At Refinery Work Wear Canada, we provide certified, high-performance high visibility rain jackets engineered for the toughest Canadian jobs. Browse our complete collection of hi-vis and FR rainwear today.